Modular Linear Actuators

Unlimited possible combinations. Customized solutions for a range of drive types and guides.

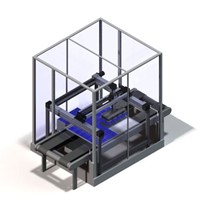

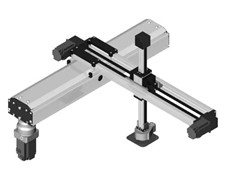

Nook Modular Linear Actuators are flexible positioning systems made of self-supporting and wear resistant aluminum profiles. Modular linear actuators can be used as a single axis solution or assembled for a multitude of gantry XY and XYZ positioning duties including inspection, pick-and-place, assembly, or dispensing applications.

Used in processes from simple positioning tasks to highly complex multi-axis systems.

Unmatched Flexibility

Over 35 models in several sizes to meet a variety of guidance, load, and speed requirements for precision applications.

Fully assembled with either roller bearing, profile rail or V-groove guidance and belt, ball screw, acme screw or rack and pinion drive. Matched non-driven models are available for system guidance requirements.

Features

- Excellent positioning accuracy

- Long service life and reliability

- High drive stiffness

- Smooth and quiet motion

- High load capacity

- Excellent efficiency

- High speeds/fast acceleration

- Long strokes

- Clean room/Explosion proof

- Temp. -25°C to +75°C

- Low maintenance/low wear

- Low breakaway/drive torque

- Self-locking

Unlimited Possibilities for Automation

Used as a single axis solution or assembled for a multitude of gantry XY and XYZ positioning duties including inspection, pick-and-place, assembly, or dispensing applications.

Modular Actuator Accessories

6 Key Design Factors for Modular Linear Actuators in Electromechanical Systems

Design Considerations when looking at a possible replacement or upgrade for an existing industrial system, modular linear actuator systems can offer advantages in most applications. Resources to...

Selecting Linear Actuators for Robotics

Click here to view...

Optimizing Diagnostic Laboratory Throughput

Medical laboratory automation has always been a great fit for the linear motion industry. However, in a post COVID-19 pandemic landscape, linear motion devices such as precision ball screws and...

Comparing Modular Linear Actuator Drive Types

There are typically four main drive types for these linear actuator systems. While there is some common functionality, each method can have several distinct advantages/disadvantages for a given given individual application. We will explore each of the drive types in further detail here....