Modular Linear Actuator Applications

Unlimited Possibilities in All Market Segments

Moving the Modern Industrial World.

Picking Systems (Warehouse)

Modern Picking and Warehousing systems require a high degree of flexibility and take up limited floor space while processing high warehouse volumes. Nook can manufacture your custom modular linear actuator system to your exact requirements including floor footprint, positioning accuracy, and throughput.

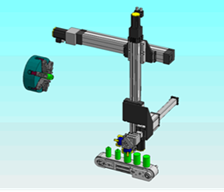

Robotics & Industrial Automation

Automated industrial robots must reliably execute dynamic motion sequences with high levels of accuracy. In the digital age of Industry 4.0, customized and flexible robot systems with ever evolving work areas are in demand. Nook modular linear actuators utilize a seventh axis, which allows us to easily meet the most demanding factory automation challenges while adapting to changing work flows.

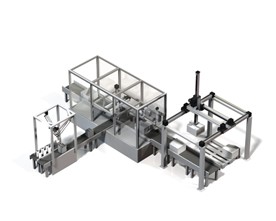

Packaging Plants

Performance and reliability are of vital importance in packaging technology. We provide customized linear axes that offer a high level of safety that can execute highly dynamic and precise linear movements with ease. Short cycle times drive high productivity allowing you to secure the competitive advantage in your packaging operations.

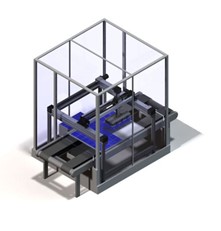

Machine Tools & Precision Machining

Efficiency, accuracy, and productivity are key characteristics for machine tools. They must be able to operate work with precision and reliability even under the most demanding industrial environments. Our linear axes can optimize your entire process from beginning to end. We have several options specifically designed to excel in extreme industrial environments.

3D Printing

3D printing demonstrates your strengths where conventional manufacturing has reached its limits. These manufacturing processes are often used in prototype construction to make components with a high degree of customization and complicated geometries. Our linear axes fulfil the requirements of 3D printing machines in terms of precision, dynamism, and operational reliability. Outperform the competition and turn your ideas into reality.

Clean Room Technology

Optimized manufacturing equipment in clean rooms and controlled areas. More importance is being placed on maintaining a high degree of cleanliness in specialized working environments. From individual rooms to complete production sites, the particle concentration in the air must be kept very low and constant conditions guaranteed. Our linear axes are certified EN, VDI, and ISO, and thereby meet the high-quality standards of clean room technology.

Explosion Protection

Safety is particularly important where flammable substances are processed. The appropriate permits and certifications are therefore necessary for explosion-proof equipment.

Our linear axes are certified in accordance with the ATEX guidelines and thereby meet the high safety requirements for the explosion protection field. Play it safe with us.

Electronics Manufacturing

The electronics industry makes up a growing proportion of the value-added chain in industry. In process and plant technology, mechanical components are increasingly being replaced by electronic components, or are at least being controlled by them. This leads to increased complexity and safety requirements. With our customized linear axes, you can meet this challenge. Precision, continuity, and reliability secure the competitive advantage.

Assembly and Production Lines

Customized system solutions are increasingly required to complete specific automation tasks relating to Industry 4.0. We provide tailor-made solutions for your needs with the highest level of performance, reliability, and minimal maintenance. The productivity of your machine is boosted thanks to reduced downtimes.

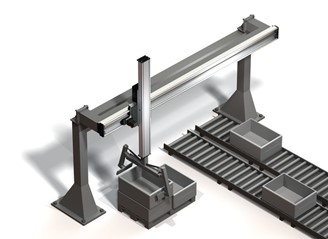

Palletizing & Material Handling

Palettizing systems with integrated handling create automated processes and handling that is gentle on parts for optimum quality. These are required to carry out linear movements precisely and reliably, and to be space-saving and easy to integrate into existing structures. A high degree of flexibility is therefore vital. We supply linear axes and multi-axis systems that meet these exact requirements.

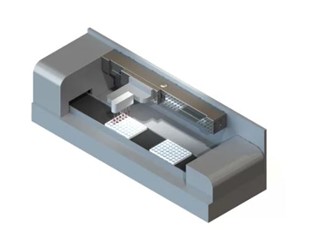

Medical & Diagnostics

In many cases, the work and logistics zones of pharma and chemical companies are comparable to hygienic dry areas. It is important that the built-in technology can be easily and effectively cleaned. Stainless-steel surfaces are particularly good in this regard. In addition, they protect the technology thanks to their high resistance to aggressive cleaning agents and corrosive chemicals.

Automotive Manufacturing

There are a huge number of processes that require fast and precise coordination on an automobile industry assembly line. Expanding your product portfolio with new models and upgrades call for a high degree of speed and flexibility. We provide customized solutions for the assembly process with fast delivery times at attractive prices.

Let's Get Your Project in Motion

Collaborate with one of our technical experts on the specifics of your application to ensure the ideal product fit that best meets your performance requirements and budget.