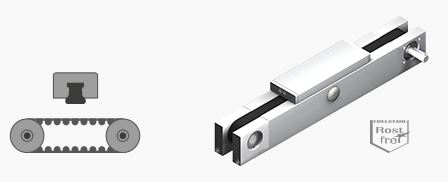

Stainless Steel Belt Driven Modular Linear Actuators

Stainless Steel Belt Driven Modular Linear Actuators consists of a square aluminum profile with an integrated ball rail and is covered by a stainless steel sheet (thickness 0.37mm, material 1.4301).

Belt Driven Modular Linear Actuators have a distinct advantage due to there ability to me manufactured in virtually any length. Models include either an external, trapped, or internal belt arraignments. The Belts are made of a high tension steel material that only requires a single adjustment after initial use. No further tensioning is required. The pulleys have maintenance free ball bearings. The belts can be supplied for clean room and explosion proof environments.

Internal Profile Rail Guided

QSZE 60, 80, 100

A square aluminum profile with an integrated ball rail guide and is covered by a stainless steel sheet (thickness 0.37mm, material 1.4301). The carriage is moved by a belt drive. Belt tension can be readjusted by a simple screw adjustment device in the carriage. This device can also be used for symmetrical adjustment of two or more linear units running parallel.

- Fitting position: As required. Max. length 3,000 mm without joints.

- Carriage mounting: T-nuts and bores through the cover.

Unit mounting: T-nuts and bores through the cover. - Belt performance: HTD with kevlar reinforcement, no backlash when changing direction, repeatability ± 0.1 mm.

- Carriage support: In the standard version, the carriage runs on two runner blocks which can be adjusted and serviced at a central servicing position. For longer carriages the number of runner blocks can be increased.

Need Help Selecting Modular Linear Actuators?

Collaborate with one of our technical experts on the specifics of your application to ensure the ideal product fit that best meets your performance requirements and budget.