From extreme temperatures to wet environments to outdoor challenges Nook Industries can meet them all.

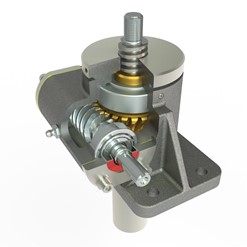

Nook Machine Screw Jacks and Ball Screw Jacks offer the ability to lift, position, hold and support loads in a variety of industrial applications. These Jacks will provide excellent performance and reliability in the average indoor industrial facility with a dry environment and an operating temperature of 32oF (0oC) – 180oF (82oC).

However, not all applications are in these ideal conditions. Nook Industries offers many options to meet non-ideal conditions.

Jack Operating Conditions

A screw jack application operating condition is defined by two criteria. The first is the environment and the second is the temperature. The environment describes the area where the screw jack application is located. The temperature describes the ambient temperature in which the screw jack will be performing.

The screw jack operating conditions can be described by one of five environmental conditions and one of three temperature conditions. When the environmental conditions and/or temperature conditions are not “Standard” then screw jack modifications are required.

Environmental conditions

- Standard - Indoor applications with dry conditions.

- Wet/Harsh - Indoor applications with wet conditions (May include water, coolant, chemical cleaners).

- Food Grade - Indoor applications with wet conditions requiring non-contact food grade considerations.

- Outdoor - Outdoor applications.

- Marine - Outdoor coastal applications with exposure to salt water and salt spray conditions.

Temperature conditions

- Standard - Application with an ambient temperature of 32oF (0oC) – 180oF (82oC).

- Low Temperature - Application where the low ambient temperature is in the range of -40oF (-40oC) – 32oF (0oC).

- High Temperature - Application where the high ambient temperature is in the range of 181oF (83oC) – 300oF (149oC).

Screw Jack Modifications

Wet/Harsh Indoor Environments

Wet and harsh environments require updates to the screw jack deign to prevent corrosion. These screw jacks will have the standard hardware and fasteners replaced with stainless steel versions of the hardware and fasteners. The seal materials will be updated for improved chemical resistance. The paint will be updated to Epoxy paint to improve the corrosion resistance and resistance to other chemicals. If a boot is required, the boot material will be updated to improve the chemical resistance.

Indoor Food Grade Environments

Food Grade environments will usually require improved corrosion resistance and chemical resistance due to required cleaning procedures. These screw jacks will have the same updates as the Wet and Harsh environment screw jacks. Additionally, the grease used for lubrication in these screw jacks will be updated to a food grade grease.

Outdoor Environments

Outdoor environments require updates to the screw jack deign to prevent corrosion and resist weathering. These screw jacks will have the standard hardware and fasteners replaced with stainless steel versions of the hardware and fasteners. The seal materials will be updated for improved weather resistance. The paint will be updated to outdoor rated polyurethane paint for corrosion resistance and outdoor use. If a boot is required, the boot material will be updated for outdoor use.

Outdoor Marine Environments

Outdoor Marine environments require different updates then non-marine outdoor environments. These screw jacks will have the standard hardware and fasteners replaced with stainless steel versions of the hardware and fasteners. The seal materials will be updated for improved weather resistance. The paint will be updated to outdoor marine rated polysiloxane paint for corrosion resistance and outdoor use in marine environments. If a boot is required, the boot material will be updated for outdoor and marine use.

Operating Temperatures where the High Temperature Reaches 181oF (83oC) – 300oF (149oC)

High operating temperatures of 180oF (83oC) - 300oF (149oC) will require design modifications to ensure jack performance is maintained. Seal materials are changed to maintain performance in the elevated temperatures. Standard grease is updated to a high temperature grease that maintains performance at the elevated temperatures. Standard paint is updated to a high temperature paint that will not degrade at the elevated temperatures. If a boot is required, the boot material will be updated to prevent temperature related failure.

Operating Temperatures where the Low Temperature reaches -40oF (-40oC) – 32oF (0oC)

Low operating temperatures of -40oF (-40oC) - 32oF (0oC) will require design modifications to ensure jack performance is maintained. Seal materials are changed to maintain performance at these low temperatures. Standard grease is updated to a low temperature grease that maintains performance at these low temperatures. Standard paint is updated to an Epoxy paint that will perform at these low temperatures. If a boot is required, the boot material will be updated to prevent temperature related failure. Low temperature applications also have the hardware and fasteners updated to stainless steel.

|

OPERATING CONDITIONS |

Exposed, Non-Painted Alloy Steel Surfaces |

FASTENERS |

SEALS |

PAINT |

GREASE |

BOOTS |

|

Standard Environment |

No Modification Required |

Alloy Steel |

Standard Material |

Enamel Paint |

Standard Grease |

Standard Material |

|

Indoor Wet / Harsh Environments |

Upgrade to Stainless Steel, Electroless Nickel Plating and/or Chrome Plating |

Stainless Steel |

Upgrade Material |

Epoxy Paint |

Standard Grease |

Upgrade Material |

|

Indoor Food Grade Environments |

Upgrade to Stainless Steel, Electroless Nickel Plating and/or Chrome Plating |

Stainless Steel |

Upgrade Material |

Epoxy Paint |

Food Grade Grease |

Upgrade Material |

|

Outdoor Environments |

Upgrade to Stainless Steel, Electroless Nickel Plating and/or Chrome Plating |

Stainless Steel |

Upgrade Material |

Polyurethane Paint |

Standard Grease |

Upgrade Material |

|

Outdoor Marine Environment |

Upgrade to Stainless Steel, Electroless Nickel Plating and/or Chrome Plating |

Stainless Steel |

Upgrade Material |

Polysiloxane Paint |

Standard Grease |

Upgrade Material |

|

Standard Temperature 32oF (0oC) - 180oF (82oC) |

No Modification Required |

Alloy Steel |

Standard Material |

Enamel Paint |

Standard Grease |

Standard Material |

|

High Temperature 181oF (83oC) - 300oF (149oC) |

No Modification Required |

Alloy Steel |

Upgrade Material |

High Temp Acrylic Resin |

High Temperature Grease |

Upgrade Material |

|

Low Temperature -40oF (-40oc) - 32oF (0oC) |

No Modification Required |

Stainless Steel |

Upgrade Material |

Polyurethane Paint |

Low Temperature Grease |

Upgrade Material |

Wet environment, outdoor environment, marine environment, food grade environment; Nook Industries has the screw jack options to meet these challenging environments. Temperatures below 32oF (0oC) or exceeding 180oF (83oC) Nook Industries has developed upgrades to meet these requirements.

Discuss your special environmental and temperature requirements with your Nook Industries Applications or Sales Representative. They will be able to apply the correct upgrades to ensure your jack will function in your application conditions.

Need help with an environmental application?