Hygienic Design Requirements

Standard design guidelines must ensure food processing machinery can be properly cleaned and sanitized after every use. Governing bodies include 3-A Dairy, USDA, etc…

Overview

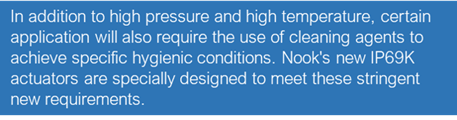

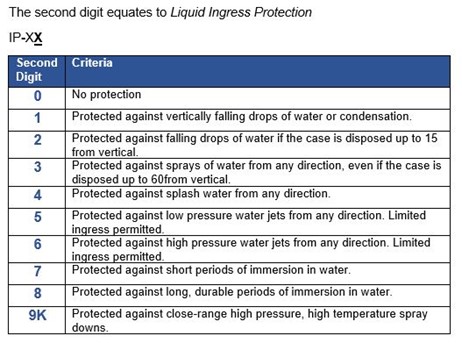

The IP (Ingress Protection) Rating system was established by the IEC 60529 standard. Recently, it was determined that the prior highest rating of IP68 was still not sufficient for enclosures that were regularly exposed to high pressure or high temperature environments such as those seen in wash down applications. Therefore, a special IP rating of IP69K was created; originating from the German standard DIN 40050-9 which evaluated road vehicles that are exposed to regular and intensive cleaning.

The requirements and testing to meet the IP69K rating in regards to waterproofing actually exceed those seen with the NEMA 4X rating. Subsequently it was found that this rating also served well to meet the cleaning requirements in hygienic applications.

Key Industries for Hygienic Applications:

- Food & Beverage Processing

- Pharmaceutical

- Medical & Diagnostics

- Chemical Analysis

- Marine and Outdoor

In addition to high pressure and high temperature, certain application will also require the use of cleaning agents to achieve specific hygienic conditions. Nook's new IP69K actuators are specially designed to meet these stringent new requirements.

Key Hygienic Requirements

These criteria are critical for electronic linear actuators to pass the rigorous testing while performing with total reliability and safety in the field.

- Should be durable and easy to clean

- Must seal tightly to prevent contaminants from mixing with product (grease, etc…)

- Exterior components constructed using 316 stainless steel (surface roughness < RA32)

- Non-steel components made using FDA approved materials

- Resistant to cleaning chemicals

- No sharp corners, crevasses, or unsealed metal areas to trap food particles

What's in the numbers?

The charts below provide more detail into what comprises the IP numbering system.

Nook SA-20 Inline Food Grade Actuator

How are Nook actuators ideally suited for the challenge?

In addition to meeting all the safety and cleanliness/cleaning requirements:

You can clean them in place while they are running.

This significantly reduces downtime because it eliminates the need for dis-assembly. Just hose them down while they are running in position.

Clean-In-Place (CIP)

A process allowing complete system cleaning without dismantling it, or the manual involvement of the operator. The insides of Nook actuators do not require cleaning (they are tightly sealed). However, the exterior can be washed down while in operation.

Nook Food Grade Actuators are fully tested to rigorous IP69K requirements. This includes many test cycles at our beta customer evaluation facilities. In addition, Nook actuators have completed the comprehensive test process for IP69K. You can trust Nook Food Grade actuators to perform in the field.

Explore Food & Beverage Applications

Need help with a specific linear motion Food & Beverage application?