Acme Screw Glossary and Technical Data

Acme Screw Glossary and Technical Data

Matched Lead

When multiple screws are used to move a load with precise synchronicity, screws of similar lead accuracy can be factory selected and supplied as sets. Consult factory for matched lead set tolerances.

Straightness

Although PowerAc™ Acme Screws are manufactured from straight, cylindrical material, internal stresses may cause the material to bend or yield.

When ordering random lengths or cut material without end machining, straightening is recommended. Handling or machining of screws can also cause the material to bend or yield. Before, during and after machining, additional straightening is required. When ordering screws with machined ends from Nook Industries, the following straightness tolerances can be expected:

PowerAc™ Rolled and Milled Acme Screws are straight within 0.010 inch/foot and will not exceed 0.030 inch in any 6 foot section, when shipped from the factory.

PowerAc™ Ground Acme Screws are straight within 0.001 inch/foot when shipped from the factory.

If tighter straightness tolerances are required, contact Nook Industries customer service.

Life

PowerAc™ Acme Screws are manufactured from high quality materials with excellent dynamic properties. Because of the variable effects of friction, lubrication and cleanliness, a specific life cannot be predicted. Proper lubrication, regular maintenance, and operation within specified limits will extend the life of PowerAc™ Acme Screws.

Efficiency

Efficiency of PowerAc™ Acme Screw assemblies range from 15% to 85%. These efficiencies are dependent upon nut material, lubrication, lead and thread form.

Backdriving

Normally, acme screws are used to convert rotary motion into linear motion. Backdriving is the result of the load pushing axially on the screw or nut to create rotary motion.

Generally, a nut with efficiency greater than 50% will have a tendency to backdrive. If a self-locking assembly is required, select a nut with efficiency below 35%.

CAUTION - Vibration can cause any acme screw assembly to creep or backdrive. When using lead screws, applications should be analyzed to determine the necessity of a brake, especially when the possibility of injury may occur.

Backlash

Backlash (lash) is the relative axial clearance between a screw and nut without rotation of the screw or nut. Backlash information for PowerAc™ Acme Screws and Nuts is listed within the data section of this catalog. Lash will always increase with use. Nook Industries has developed several unique ways to reduce or remove the lash between the screw and nut.

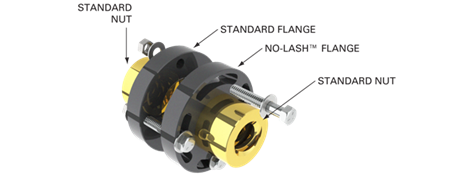

For screw diameters over 5/8 inch, PowerAc™ No-Lash™ Flanges are available. The PowerAc™ No-Lash™ Flange is identical to a standard flange except for slotted mounting holes. The backlash can be removed by using a nut with a PowerAc™ No-Lash™ Flange in combination with a standard nut and flange. By rotating the slotted PowerAc™ No- Lash™ Flange and nut relative to the other, the thread in the second nut advances until the lash is reduced.

As the nuts wear and backlash increases, loosen the mounting bolts and readjust the PowerAc™ No-Lash™ Flange and nut until the lash is minimized.

For a complete PowerAc™ No-Lash™ Flange assembly order 2 standard nuts, 1 standard flange and 1 No-Lash™ Flange. For example a 3/4" -2 assembly requires the following:

- 2 - 20072 Standard Nuts

- 1 - 70262 Standard Flange

- 1 - 73262 No-Lash™ Flange

CAUTION - When the uncompensated lash is equal to or greater than times the pitch, the assembly should be replaced.