Your Trusted Linear Motion Partner

Over 50 Years of Quality Manufacturing

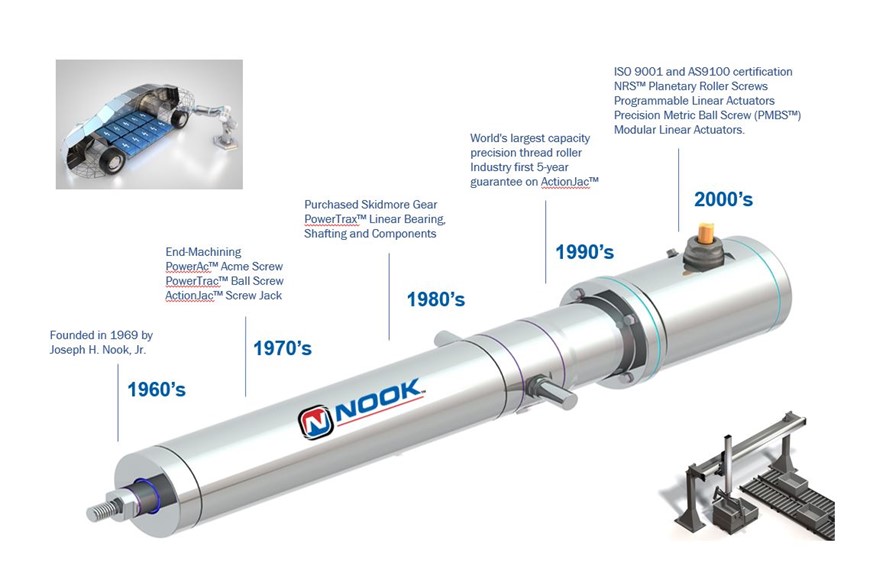

Founded in 1969 by Joseph H. Nook, Jr., Nook is a manufacturer and supplier of premium linear motion solutions with a strong presence in the Greater Cleveland community. We provide our clients with proven knowledge and flexibility to design, engineer, and manufacture quality linear motion systems and solutions for their most challenging applications. In 2021, Nook was acquired and integrated into Thomson Industries, Inc. With this partnership, we are sharing and building on the strengths of each organization, and now offer our customers nearly 130 years of combined linear motion expertise.

| Fast Facts | |

|---|---|

| Products | Ball Screws, Acme Screws, Screw Jacks |

| Founded | 1969 |

| Location | Cleveland, Ohio |

| Facility | 115,000 sq. ft. |

A History of Successful Innovation with a Proven Track Record of Consistent Growth

Industry leading brands uniquely positioned to drive innovation, accelerate growth and build value for customers. A premier linear motion company driven by the relentless pursuit of continuous improvement and customer satisfaction.

As a result of our recent acquisition, our portfolio of highly engineered products now includes Thomson ball and lead screws, electric linear actuators, Linear Ball Bushing® bearings and guides, linear motion systems, stepper motor linear actuators, ball splines, screw jacks and more.

Vertically Integrated Manufacturing

All of our Design, Manufacturing, and Quality functions are fully integrated within the same Cleveland, Ohio facility.

- Increased supply chain flexibility and control

- Lower transportation costs

- Less dependency on 3rd party suppliers

- Continued investment in capability expansion

- Tightly controlled manufacturing process

- Close coordination between functional groups (Design for Manufacturing)

- Fast response to support custom requirements

- Highly accessible technical support

Highly Specialized In-House Assets and Capability

- Precision Thread Rolling: Regular production ¼" – 6" diameter, ability to roll up to 14" diameter

- In-house ability to heat treat solid and hollow ball screws and linear shafting

Rigorous Process Control

Our quality systems are geared to support demanding applications such as aerospace, defense, and medical.

We accomplish this with a rigorously controlled process integrity that includes Lean Manufacturing, 5S, and Six Sigma. Our Quality systems emphasize continuous improvement, defect prevention, statistical methods, and ongoing training to increase the knowledge and skills of all employees.

Our Facility Is

- IS0 9001 Certified

- AS9100 Certified

- ITAR Registered

Engineering and Testing Capabilities

We Provide Concept to Launch Engineering Support for Custom Applications

Design Support

Nook understands that each project and company can have different requirements. That's why we strive to be flexible in delivering the right level of support most appropriate for each individual project. Our team of proven, highly experienced engineers (many with 20+ years in the industry) has deep linear motion technology expertise. They can tailor a perfect solution to best fit your specifications, budget, and schedule.

Functional Testing

We apply solid modeling and finite-element analysis (FEA), as well as industry best practices such as tolerance analysis, risk analysis, and comprehensive testing protocols to ensure all products perform to exact requirements. We also offer life testing with predictive tools, data for prognostics, performance wear models, and proof testing under multiple operating conditions helps to reduce design cycles.

A Complete Portfolio of Solutions

Product Durability, Flexibility, and Performance are Nook hallmarks.

You can trust our products to deliver reliable performance year after year because they benefit from over 50 years of engineering and manufacturing experience. We utilize the highest quality raw materials in our products while providing extensive on-going training to our team. Every part in a Nook product is inspected and tested before assembly, and every system that comes off our line is fully tested prior to shipment. This craftsmanship provides unmatched reliability for the your most demanding applications in the toughest environments.

Our offerings range from Acme or ball screw assemblies to electric actuators, to jacks, to modular actuators. Nook delivers maximum flexibility to machine developers by providing complete linear motions solutions with a multitude of:

- Configurations

- Mounting options

- Sizes

- Accessories

We are committed to reducing customer development cycles by providing an abundance of easy-to-use resources including:

- Downloadable 3D Models

- Design Tools

- Product Configurators

- Application Specific Tools

Let us improve your equipment designs while increasing efficiency and lowering costs.

Collaborate with our highly experienced engineering team early in the design process to integrate a complete linear motion solutions with the optimal balance of performance, life, and cost for your next application.