When not ordered as part of an assembly, ball nuts are shipped on arbors. Transferring the ball nut from the arbor to the ball screw is achieved by placing the arbor against the end of the screw thread and carefully rotating the ball nut onto the screw from the arbor. If the inside diameter of the arbor is too small to slip over the outside diameter of the journal, apply tape to the journal to bring the outside diameter up to the root diameter of the screw to prevent the bearing balls from falling out of the ball nut. The ball nut can then be transferred across the taped journal onto the ball screw.

CAUTION: Removal of the arbor from the ball nut will result in the loss of the bearing balls. All of the bearing balls in a ball nut are matched. If any balls are lost during this transfer, they all must be replaced.

- Remove any ball nut retainer from arbor. Hold arbor firmly end to end with the screw. Make certain the arbor end is centered on the screw shaft end.

- Slide the ball nut down the screw shaft and rotate counter to the thread until you feel the balls drop into the screw thread. Then rotate with the screw thread until the ball nut completely clears the end of the screw shaft adjacent to the arbor.

- Remove the arbor.

To transfer the ball nut from screw to arbor, reverse the above procedure.

CAUTION: Extreme care must be taken to prevent the ball nut from sliding off the end of the screw shaft during installation and handling. Temporary stops can be made by wrapping tape around shaft balls grooves at each end. Be sure to remove tape and any residual adhesive after the ball screw assembly is properly installed.

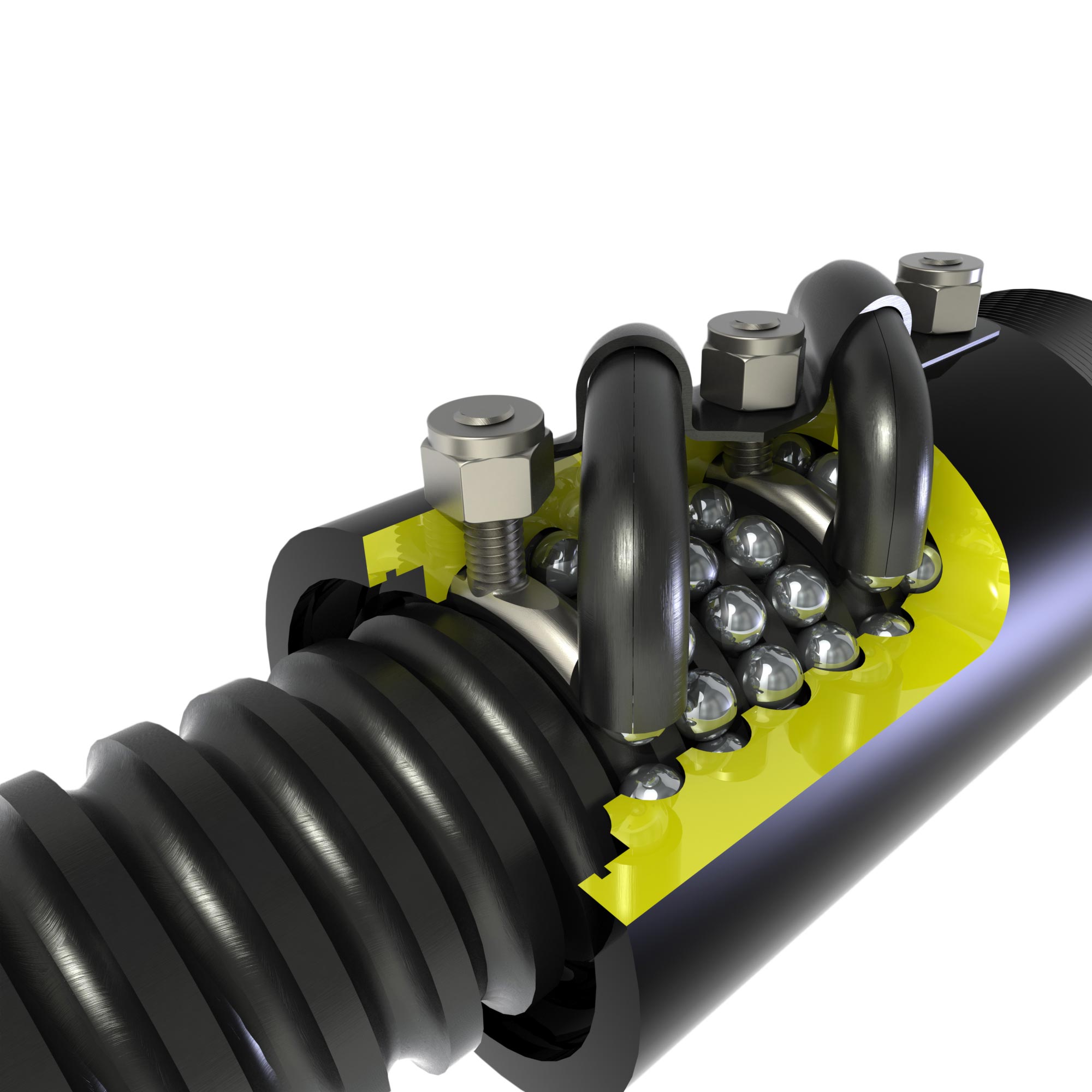

Installing SEL, SAR, and SAG Ball Nuts

These nuts must be transferred from the arbor to the screw without preload. Be sure to keep the ball return tubes aligned with each other and make sure the coupling tangs line up with the slots in the ball nut.

Center the adjusting nut on the coupling. Before preloading these ball nuts, all the coupling threads, spring washers/spacers and ball grooves should be lubricated.

Position the ball nut on the center of the screw shaft. It is a good idea to place retainers (tape, tie-straps, etc.) on the screw to prevent the ball nut from over-traveling. With the ball return tubes facing upward, tighten the adjusting nut against the spring washer or spacer by hand until it cannot be turned. While holding the ball nut with tubes facing up, rotate the screw several turns in both directions.

Running torque can be measured by means of a spring scale. The force reading multiplied by the lever arm length yields the running torque value.

Make adjustments to achieve desired preload and recheck running torque value up and down the screw shaft. Do not tighten the adjusting nut to a point that fully collapses the spring washers. After the system is adjusted, secure the adjusting nut with the set screws provided.