A Rapidly Evolving Diagnostics Landscape

Medical laboratory automation has always been a great fit for the linear motion industry. However, in a post COVID-19 pandemic landscape, linear motion devices such as precision ball screws and modular linear actuators will play an ever-increasing role in improving laboratory throughput, efficiency, and reliability. Ultimately, this provides physicians, clinicians, and patients with accurate test results in the shortest period of time.

The range of applications for linear drives in the medical industry segment is extremely broad. In this blog, we will focus on large-scale automated diagnostic analyzers used in high volume test sample processing.

Laboratories around the world are now experimenting with new tests and methods to provide faster and even more reliable automation for mass-scale screening and virus detection. As a result, linear motion device manufacturers will need to focus on improving laboratory throughput without sacrificing quality and reliability.

Minimizing human interaction is key to achieving fast and easy handling of time-sensitive samples in these extremely busy laboratory environments. Typically, the human interaction involves reagent and consumables loading, racking/inserting RFID or bar-coded trays, emptying waste and results interpretation. These test results can be automatically sent to remote laboratory information system (LIS) and electronic medical record (EMR) networks for further analysis and diagnosis.

Selecting the proper linear motion device into these highly demanding applications can be challenging when there are many different linear motion technologies to choose from. The value to equipment manufacturers, medical facilities, and patients is dependent on proper selection and implementation of linear motion devices. This is what ultimately drives Overall Equipment Effectiveness (OEE) of the automated diagnostic systems. IE: How well a process is utilized (facilities, time, and material) compared to its full potential.

Typical laboratory demands include:

- Reliability

- Precision and Repeatable Movement

- Size Limitations

- Noise Restrictions

- Speed and Efficiency

There are two types of linear motion product lines that stand out for these types of automated laboratory equipment situations:

- Ball Screw Assemblies

- Linear Modular Actuators

Before choosing between the two, it is important to understand the type of application that your equipment design will be supporting. In many cases both technologies are paired within the same equipment for different functions.

Ball Screws

Historically, ball screw assemblies have been the “go-to” linear motion device for medical and laboratory equipment applications. This is because they have provided a myriad of effective solutions for equipment designers. They simply have an outstanding track record for meeting medical research instrumentation requirements.

Ball Screw Assembly with Motor

In this specific area of medical diagnostic analyzers, ball screws are ideal for set-up applications that can include ergonomic adjustable stands for computers and x-ray equipment, along with positioning and inspection cameras, label makers, and printers.

Want to learn more?

Our Engineering Director and resident linear motion expert, Alex Margolin has written extensively on applying precision ball screws in medical applications. You can view his latest white paper by clicking the link below.

Modular Linear Actuators

How can modular linear actuators improve the test process?

Automation and Robotics. These linear motion systems in particular, make it possible to execute the massive volume of tests that are required during global health related emergencies such as the SARS outbreak and COVID-19 pandemic. During these fast-paced operations, samples, and consumables must be loaded, unloaded, and transported through the various steps of the diagnostic process. In addition, sensitive fluid handling is required at various stages of the diagnostic testing.

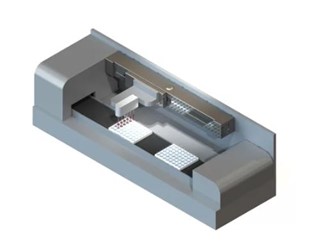

Linear Modular Gantry System

Specialized applications of Modular Linear Actuators:

- Driving conveyors or transporting samples

- Gantry robotics (Cartesian) for fluid handling, sample extraction, and liquid dispensing

- Gantry robots for sample tube handling

- Labeling and bar coding sample tubes

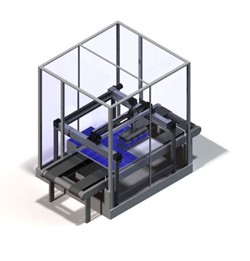

Medical Diagnostic Analyzer

Other applications include:

- Pick and Place

- Blister & Tray Handling

- Test Specimen Handling

- Filling

- Metering/Counting

- Insertion and Closures

- Carton Packaging

- Labeling

Modular Linear Actuators can support robotic systems that work faster and longer. Plus, they minimize errors when managing critical patient samples and provide highly precise positioning that prevents spilling fluids and reagents. Modular Linear Actuators significantly increase test processing capacity, reduce error instances, and improve the ability to track samples. This in turn, increases the overall safety of laboratory personnel due to less risk of contact with contagions.

Hygienic Designs

These laboratory environments also require hygienic designs of the linear motion devices to these highly sensitive samples in accordance with clean room regulations. Their facilities for the industry must meet the highest quality and safety standards. Modular Linear Actuators are ATEX-certified for areas of application such as vacuum technology, clean room technology, and explosion protection. They are highly configurable and can be customized to adapt to any situation. The stainless steel surfaces can be easily and effectively cleaned, and they are highly resistant to various cleaning agents and corrosive chemicals. The modular linear actuators utilize plain and closed profile surfaces and geometric forms to facilitate easy cleaning.

Clean Room Linear Actuator System

Space Saving Technology

When labs invest in automated warehouse logistics, the process usually involves modifications to existing premises. As a result, the testing area is subject to structural restrictions. System manufacturers of linear motion positioning technology systems must therefore be able to adapt. These linear motion systems are easily configured in terms of length and function. This modularity a valuable degree of flexibility for optimizing a lab’s available facility layout.

Modular Linear Actuators

Modular Linear Actuators