A Heightened Focus on Reshoring

Over the last few decades, many companies across all industries have invested significant effort and cost to offshore the manufacturing of their products to countries with more attractive wages. In addition, these countries are relatively loose in their regulations. This made it easier to manufacture with flexibility and increase profits further.

The costs and risks of lengthy supply chains have been exposed in the wake of the COVID-19 pandemic. This is driving more companies to consider reshoring their overseas operations to the United States.

Reshoring includes not only relocating existing manufacturing back to the United States, but also new investment in domestic plants that might have gone overseas.

Not Just Medical Supplies

The supply chain disruptions experienced during the pandemic will impact future business decisions across a variety of market segments. This trend is beginning to extend beyond medical to other industries. This includes electronics, aerospace, automotive, defense and consumer products.

Benefits of Reshoring

1. Comprehensive Quality Control

Quality is a critical consideration for most manufacturers. However, it is especially critical for high technology industries such as medical, aerospace, transportation, and defense. It is much easier to manage the quality of suppliers when they are in the same region as a manufacturer.

Closer is better for communication and management of critical to quality parameters. In addition, regions with more mature and established regulatory systems generally create higher quality products as a benefit of more stringent oversight.

2. Significantly Streamlined Logistics

It is much easier to control and manage inventory when it is not tied up in the many forms of transit and storage. Waiting to make changes or upgrades to a product once it arrives (as opposed to on the fly), often times causes major delays in lead time. In addition, there are obviously much lower shipping costs without all of the red tape associated with international transport.

3. Availability of Skilled Workforce

The United States has millions of talented, highly skilled workers throughout the country. This has historically been a strong juggernaut for innovation and that trend will assuredly continue as more manufacturing is brought back (innovation and manufacturing typically have a strong correlation).

4. More Effective Facility Management

Companies with overseas facilities often encounter a variety of discrete costs, risks, and organizational challenges associated with a remote footprint. Improvements and updates to processes or systems can be very tricky when implemented at different locations by individual teams. General oversight is simplified, and costs are reduced when visiting a different part of a building versus travelling to different part of the world.

5. Simplified and More Efficient Supply Chain

Components for end products that originate from local suppliers greatly increase the overall efficiency of supply chain management. It is also beneficial to collaborate with suppliers in a region that share similar business philosophies (Including quality management systems). It is much more efficient to collaborate with a team in a similar time zone (a few hours as opposed to 12). This also eliminates many of the language barriers that can sometimes exacerbate issues.

6. Local Manufacturing Fosters U.S Innovation

Innovation has historically gone hand-in-hand with manufacturing. Having U.S. citizens actively engaged in the process of manufacturing will inherently drive new inventions that naturally occur from this process.

7. More Americans Participate in the Economy

Returning manufacturing to the United States will also help offset millions of lost jobs as a result of the COVID-19 stay-at-home orders. While it is expected that good numbers will return to work as order is restored, certainly many will not. A larger percentage of employed Americans will significantly benefit all segments and industries. Everyone wins when more of us are actively participating in the economy together.

8. Avoiding Expensive and Complex Taxes/Tariffs

Initially, many companies were willing to absorb the higher tariff costs, however this surely not the best long-term option. Eventually, these higher tariff charges must be passed on to the end customer. Ultimately, this will result in lost market share for many product-based businesses.

9. Intellectual Property Protection

Intellectual property is not fully protected in the same manner globally as it is in the United States. The protections in the United States and Europe are far superior to those in many other parts of the world. Having sound and organized legal recourse is an ideal option in a situation when your IP is stolen.

10. Simplified Legal Issues

The legal system can be extremely beneficial for long-term stability in all areas of a business. Managing multiple legal systems (across different countries) is significantly more challenging. Certification for countries outside of the United States is generally much easier to obtain using U.S. based labs and institutions.

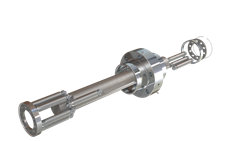

High-quality components are a cornerstone of a high-quality assembly.

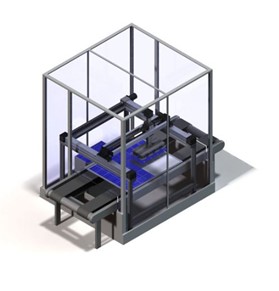

Nook is your trusted onshore resource for linear motion solutions.

All of our operations are co-located in one U.S. based facility. In addition, we have a vertically integrated supply chain that provides you with unmatched flexibility, quality, and service.

Our supply chain is fully engaged to integrate with your supply chain.

Explore Nook Onshore Capabilities

Need help with a linear motion project?