Linear Motion Technology for Clean Rooms

What special requirements do our customers usually have in markets such as chemical, pharmaceutical, and semiconductor processing?

These work zones can be compared with hygienic dry areas in many respects. The built-in linear motion technology must be spray-proof and water resistant. Therefore, it is important that the mechanical components can be cleaned easily and effectively. In addition, the surface protects the internal mechanics from aggressive cleaning agents and corrosive chemicals due to their high resistance. Surfaces made of stainless steel are ideal for these applications.

In production in Clean Rooms, the concentration of airborne particles is kept particularly low to prevent defects and reduce losses. In recent years, increased quality standards have led to a high interest in clean room standards in many production facilities. Specific manufacturing functions can include filling, packaging, testing, sorting, and positioning.

Clean Room Solutions

How does our linear actuator technology meet the demanding standards of our customers?

What makes our products so special?

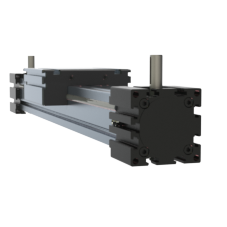

The aluminum guide profiles of the linear actuators are clad with a stainless steel sheet (thickness 0.37 mm, material 1.4301) using a highly specialized process. This stainless steel casing provides the highest hygiene standards. In addition to the built-in rustproof components inside the linear actuator, the smooth outer surface of the system can also be cleaned very easily.

With its complete stainless steel sheathing, the axle is not only protected against coarse external influences, but is also particularly easy to clean due to its smooth surfaces. High-quality materials are used to effectively limit the abrasion of moving parts.

These linear axes have proven to be particularly useful in the food & beverage, pharmaceutical, chemical processing, and semiconductor industries. In addition, machine builders can easily integrate these linear positioning systems into their applications. Our modular linear actuator products can be tailor-made to integrate into production facilities in clean and clean rooms. Our customers can easily certify their automated systems in clean room areas.

Our linear axes are certified according to the following standards:

- US Federal Standard 209E Class 1 – 100,000

- VDI 2083 Class 1 – 6

- ISO 14644-1 Class 1 – 8

Explore Nook Clean Room Rated Actuators

Use Our Linear Actuator Product Selector

Easily design your own linear actuator system based on your unique application with the DESIGN GUIDE PRO tool. Enter your parameters to determine the best product fit.

Get Help with an Application

Special circumstances can sometimes require tailor-made solutions. Often the problem cannot be solved by just using individual stainless components.

Our engineering team not only advises you on the provision of the ideal linear unit for your machine design, but also supports you with questions about production in clean rooms. As always, our Engineering Support Teams are always on stand-by to help with your linear motion application.