Factory Automation

Nook's linear motion products enhance efficiency, safety, equipment performance and process while maximizing asset utilization.

Specialized low maintenance solutions provide superior quality, unmatched reliability for enhanced equipment productivity.

Customized automation system solutions are increasingly required in order to complete specific automation tasks relating to Industry 4.0.

Factory automation describes the process of incorporating automated machines to manufacture end products or components. This includes assembly lines and robotics that are integrated with hardware, motors, controls, and software.

Typical Automated Functions

- Arc Welding & Spot Welding

- Assembly

- CNC Milling & Turning

- Dispensing, Painting, and Sealing

- Laser Cutting & Machining

- Palletizing, Picking and Packing

Precision Assembly Operations

Smooth, frictionless travel at all speeds.

Precision automated assembly requires constant back and forth movement at higher speeds. As a result. peak performance is required from linear motion technologies (often under clean room conditions) for these applications.

Nook linear motion systems are designed to perform reliably in tough, continuous operation conditions. These linear motion systems deliver precision, repeat accuracy, and reliability under continuous operation.

Ease of synchronization provides an inherent advantage in producing sound welds while eliminating hypercritical settings to provide unmatched precision. Nook linear motion systems provide smooth, frictionless travel at all carriage speeds, plus reliable, trouble free service coupled with minimal maintenance. Mechanical actuation also helps to reduce floor space.

Typical Applications

- Welding, Soldering, Cutting, Drilling, Painting

Microelectronics Automation

- Chip-on-board mounting

- Chip-on-flex mounting and connecting

- Gold-to-gold flip-chip interconnecting

- Hybrid integrated circuit construction

- Multichip module assembly

- Wafer-level packaging, bumping,

- Wire bonding

Printing & Scanning

Flexibility for printing, labeling and scanning.

Nook provides the accuracy, high speed, and flexibility with minimal engineering effort for printing, labeling and scanning operations. This includes gantry systems with linear guide and ball screw components utilized on conveyors with visual recognition systems that transport items of varying size for printing (or scanning) while in motion.

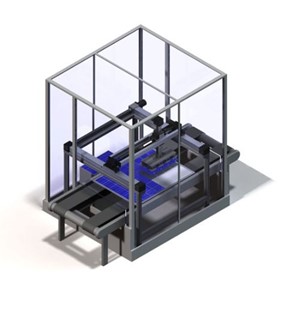

3D printing is ideal when conventional manufacturing has reached its limits. These manufacturing processes are often used in prototype construction, for components with a high degree of customization, and with complicated geometries.

Linear axis systems are an essential feature in 3D printers. They position the laser head in the portal group and feed in material layer by layer. Nook linear axes are used in challenging environments that call for a high level of positioning and repeatability in non-stop 24/7 operations.

Robotics

Industrial robots are used for manufacturing end products and components. They are automated, programmable and capable of motion on three or more axes. All of this must be accomplished with high endurance, speed, and precision.

Robots on Rails

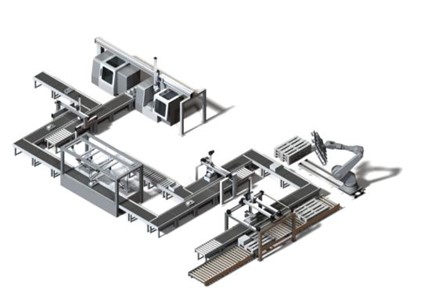

Industrial Automation

Reduce manufacturing costs with higher production rates.

High functional integration is a primary characteristic of fully automated manufacturing lines. The key is to combine as many work steps as possible in a small space – and to then make the work cycle as fast as possible. With regard to the custom manufacture of products, adaptability and flexibility are also important for the manufacturing and assembly technology of tomorrow.

Nook products are ideal for automated assembly machines that require high reliability, efficiency, and positioning accuracy to reduce manufacturing costs by generating higher production rates.

Ultimately, it’s all about realizing requirements while collaborating perfectly with the machine builder.

Typical Applications

- Automotive

- Electronics Assembly

- Semiconductor Manufacturing

- Large Scale Production Lines

Test & Measurement

Accurate Measurements = Superior Quality.

Automated test systems are utilized by research and development, manufacturing quality control, and government laboratories. Nook products optimize automated test and measurement operations with stepless control and continuous positioning of the drive and stage while providing highly accurate linear motion in both X and Y axes.

Typical Applications

- Test and develop new products

- Benchmark and certify products

- Ensure quality on a manufacturing line

Modular linear actuators can be used as a single axis solution or assembled for a multitude of gantry XY and XYZ positioning duties for various inspection and test applications.

Equipment Systems

- Vision & optical inspection

- Torque & Force

- Characterization

- Vibration

- Probing & Gauging

Faster Speeds with Greater Accuracy

Selecting Linear Actuators for Robotics

Click here to view...

Linear Actuators for Automated Packaging

Click here to view...

Electric Linear Actuators: Moving Modern Industry

Explore the limitless automation applications of these extremely versatile and highly dynamic linear actuators....

Electric Cylinder Application: Foundry Automation

These heavy duty electric cylinders will optimize the linear motion of equipment used in the Metal Casting Industry....