Clean Room Rated Belt Driven Modular Linear Actuators

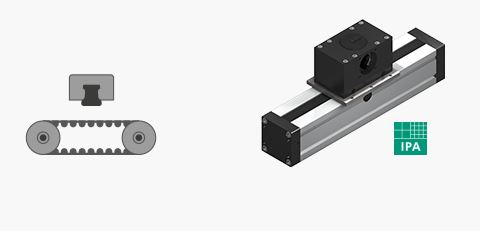

The carriages are driven by either a trapped or internal linear belt that can be adjusted to reduce lash is driven along the external roller bearings. This arrangement allows for easy adjustment and belt tensioning, which can be readjusted by a single screw adjustment device in the carriage. The pulleys of belt driven modular actuators have maintenance-free ball bearings.

Optimized manufacturing in clean rooms and controlled areas. More and more importance is placed on maintaining the cleanliness of working environments. From individual rooms to complete production sites, the particle concentration in the air must be kept very low and constant conditions guaranteed. Our linear axes are certified EN, VDI, and ISO, and thereby meet the high quality standards of clean room technology.

Our linear axes are certified in accordance with the following:

- US Federal Standard 209E Class 1 – 100,000

- VDI 2083 Class 1–6

- ISO 14644-1 Class 1–8

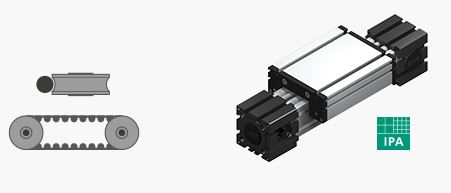

External Roller Bearing Guided

An aluminium square profile with integrated, hardened steel guide rods. The carriage, which has internal linear ball bearings that can be adjusted free of play, is driven along the guide rods by a timing belt. Toothed pulley has maintenance-free ball bearings. Belt tension can be readjusted by a simple screw adjustment device in the carriage. This device can also be used for symmetrical adjustment of two or more linear units running parallel.

This linear unit is suitable for application in clean rooms of clean-room classification 1,000 (corresponding to US Fed. Standard 209 E).

- Fitting position: As required. Max. length 3,000 mm without joints.

- Carriage mounting: T-slots.

- Unit mounting: Tapped holes or tapped holes in the bearing block, mounting sets.

- Belt type: HTD with steel reinforcement, no backlash when changing direction, repeatability ± 0.1 mm.

ELHZ 60, 60S, 80, 80S, 100, 125

Internal Belt Drive Horizontal Mount

ELVZ 60, 60S, 80, 80S, 100, 125

Internal Belt Drive Vertical Mount

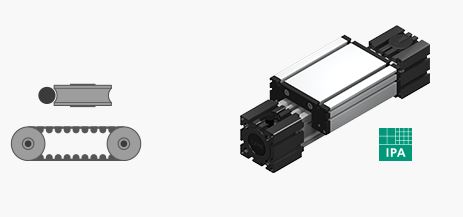

Internal Roller Bearing Guided

Trapped Linear Belt Driven

A square aluminium profile with an integrated roller guide. The carriage is driven by a timing belt. Each standard pulley includes one coupling claw on one side. Belt tension can be readjusted by a simple screw adjustment device in the carriage. This device can also be used for symmetrical adjustment of two or more linear units running parallel.

This linear unit is suitable for application in clean rooms of clean-room classification 1,000 (corresponding to US Fed. Standard 209 E).

- Fitting position: As required. Max. length 6,000 mm without joints.

Carriage mounting: By T-slots. - Unit mounting: By T-slots and mounting sets. The linear axis can be combined with any T-slot profile.

- Belt performance: HTD with steel reinforcement, no backlash when changing direction, repeatability ± 0.1 mm.

- Carriage support: In the standard version, the carriage runs on 4 rollers which can be adjusted.

QLZ 60, 80, 100

Internal Roller Bearings with a Trapped Belt Drive.

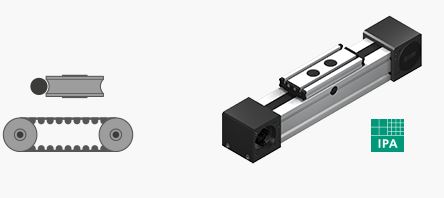

Internal Profile Rail Guided

QSZ

A square aluminium profile with an integrated roller guide. The carriage is driven by a timing belt. Each standard pulley includes one coupling claw on one side. Belt tension can be readjusted by a simple screw adjustment device in the carriage. This device can also be used for symmetrical adjustment of two or more linear units running parallel.

Suitable for application in clean rooms of clean-room classification 1,000 (corresponding to US Fed. Standard 209 E).

- Fitting position: As required. Max. length 6,000 mm without joints.

- Carriage mounting: T-slots.

- Unit mounting: T-slots and mounting sets. The linear axis can be combined with any T-slot profile.

- Belt performance: HTD with steel reinforcement, no backlash when changing direction, repeatability ± 0.1 mm.

- Carriage support: In the standard version, the carriage runs on 4 rollers which can be adjusted.

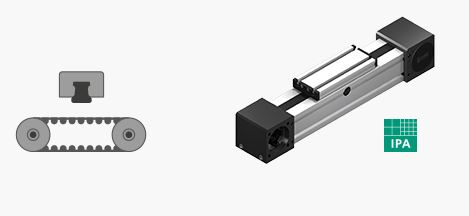

QSSZ

A square aluminium profile with integrated rail guidance. The carriage, which has runner blocks, is driven by a timing belt. Each standard pulley includes a coupling claw on one side and is equipped with maintenance-free ball bearings. Belt tension can be readjusted by a simple screw adjustment device in the carriage. This device can also be used for symmetrical adjustment of two or more linear units running parallel.

- Fitting position: As required. Max. length 3,000 mm without joints.

- Carriage mounting: T-slots.

- Unit mounting: T-slots and mounting sets. The linear axis can be combined with any T-slot profile.

- Belt performance: HTD with steel reinforcement, no backlash when changing direction, repeatability ± 0.1 mm.

- Carriage support: In the standard version, the carriage runs on 2 runner blocks which can be serviced at a central servicing position. For longer carriages the number of runner blocks can be increased.

Need Help Selecting Modular Linear Actuators?

Collaborate with one of our technical experts on the specifics of your application to ensure the ideal product fit that best meets your performance requirements and budget.