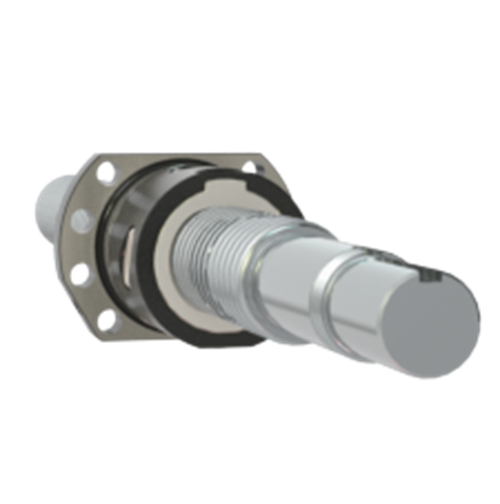

Ball Screw

Hundreds of precision ball screw different designs to meet virtually any performance criteria.

Our ball screws can be supplied completely machined and assembled with nuts, flanges, wipers, and EZZE-MOUNTS. Ball nuts are offered in standard and preloaded designs.

If a standard assembly does not fit the application, Nook can machine a ball screw to your specific design requirements. Custom sizes and configurations are available.

Ball Screw Advantages

Ball screws offer a highly efficient means of converting rotary motion to linear motion. Precision ball screws have several bearing balls that transfer the load between the nut and screw.

- Improves speed, force, and duty cycle

- Longer and predictable life cycle

- Requires less motor power

- Heavier loads

- Greater accuracy

- High efficiency (less friction)

Ball screws are cataloged by screw thread accuracy: standard rolled, precision rolled and ground.

Engineering Resources

Ball Screw Engineering Calculators, Engineering Tools, & Technical Information. A comprehensive library of helpful ball screw resources.

Unmatched Manufacturing Capability

- Precision Thread Rolling: Regular production ¼" – 6" diameter, ability to roll up to 14" diameter

- In-house ability to heat treat solid and hollow ball screws and linear shafting

- The latest in CNC thread rolling technology and state of the art CNC induction heat treatment

Rolled ball screws nearing precision ground accuracy at a substantially lower cost.

Ball Screw - Inch Standard Accuracy (SRT)

Standard Rolled Thread Ball Screw (commercial or transport type)

Offer the low friction advantage of antifriction screws at lower cost. They are capable of higher speeds and longer predictable life when compared to similar acme type lead screws. Part Number Reference

- Leads from .125” to 1.875”

- Offered with OD threaded, non-preloaded ball nuts.

- Available with integral flange nuts and/or with double nuts with spring loaded adjustable preloading feature for eliminating backlash.

| Material | Surface | Lead Accuracy |

| Alloy | Black | ± 0.004 in/ft |

| Alloy | Black | ± 0.008 in/ft |

| Stainless | Polished | ± 0.004 in/ft |

| Screw Diameter | Screw Lengths |

| 0.375" to 2.500" | Up to 24' |

| 3.000" to 6.000" | Up to 24' |

| 0.375" to 1.000" | Up to 24' |

Ball Screw - Inch Standard Accuracy (SGT)

Standard Ground Thread Ball Screw

Ground from high carbon alloy steel that has been induction heat treated to a depth greater than the thread. Ground ball screws are used for applications that require smooth operation, precise positioning, and repeatability. Part Number Reference

- Standard ball screws are supplied with internally preloaded nuts (must be factory assembled).

| Material | Surface | Lead Accuracy |

| Alloy | Polished | ± 0.0005 in/ft |

| Screw Diameter | Screw Lengths |

| 0.631" to 2.500" | Up to 10' |

Ball Screw - Inch Precision Accuracy (XPR)

Precision Rolled Thread Ball Screw

Offered with leads of 0.200” to 0.500” depending on diameter. Nook uses the latest in CNC thread rolling technology and state of the art CNC induction heat treatment to manufacture a rolled screw with accuracy approaching precision ground at a substantially lower cost.

They fill the need for applications that don’t warrant the expense for ground screws but still require more precise positioning than that offered by commercial grade screws. Part Number Reference

- Standard lead accuracy: ±.001 in/ft

- Offered with internally preloaded non-adjustable ball nuts with either an integral flange or an OD thread which allows for the use of a custom flange to fit a specific need.

Ball Screw - Precision Metric Ball Screw (PMBS™)

Precision Metric Ball Screw Assemblies

Provide very high accuracy at reduced costs. High-lead precision rolled ball screws achieve maximum travel rates with repeatable positioning accuracy. All ball nuts are precision ground and engineered to operate with precision rolled ball screws or precision ground (T3) ball screws.

- Lead accuracy classes of T10, T7, T5, and T3, which comply with the ISO 3408 ball screw standard.

- Precision thread-rolling and heat treating technology

- Wide range of diameters and leads

- DIN-style flanges

- Preloaded and clearance nuts

- State-of-the-art ball return mechanisms

- Integral wipers

Miniature Ball Screw - Metric

Small Diameter Ball Screws

6mm - 14mm Diameter

For decades, Nook has produced custom small diameter ball screws and nuts for the aerospace and medical industries; these standard metric miniatures are the result of that experience. Available in alloy or stainless steel, small diameter screws provide engineers a globally accepted product for smaller footprint applications that demand high accuracy, repeatability, and durability. Part Number Reference

We are a leading producer of miniature ball screws and offer a wide variety of sizes and configurations.

- The miniature product line is supplied as a complete assembly.

- Screw ends can be machined to customer requirements in nearly any diameter and length configuration.

Ball Screw - Metric Standard Accuracy (MRT)

Metric Rolled Thread Ball Screw

Feature precision ball nuts that are an economical, high-performance alternative to ground thread ball screw assemblies. MRT Rolled Ball Screws are manufactured under tightly controlled conditions in the rolling process. Uniform heat treatment is monitored by temperature sensors to ensure high quality and accurate lead. Part Number Reference

- Standard lead accuracy: ±100μm / 300mm

- The ball nut assemblies ensure accuracy, zero backlash, consistent repeatability, and high system stiffness at low running torque. Ball nuts can be assembled with a selective fit to minimize lash.

Ball Screw - Metric Precision Accuracy (PMT)

Precision Rolled Ball Screw

Feature precision ground preloaded ball nuts that are an economical, high-performance alternative to ground thread ball screw assemblies. They are manufactured under tightly controlled conditions in the rolling process. Uniform heat treatment is monitored by temperature sensors to ensure high quality and accurate lead. Part Number Reference

- Standard lead accuracy: ±25μm / 300mm

- The preloaded ball nut assemblies ensure accuracy, zero backlash, consistent repeatability, and high system stiffness at low running torque.

- Ball nuts feature a unique solid preload that enhances system smoothness, and are factory-fit on the ball screws, providing a backlash-free system for long life.

Medical Motion: Precision Ball Screw Technologies

Click here to view...

Ball Screw Design - Safety Considerations

Ball screws provide several unique benefits when compared to other standards, such as roller screws or acme screws. Just a few of these include:...

Ball Screw Application: Precision Machining

Precision machining is a type of technical manufacturing that is essential in creating and designing machines, parts, tools, and other hardware that are essential in modern...

Miniature Ball Screws: Big Efficiency in a Small Package

Miniature Metric Precision Ball Screws Miniature Metric Precision Ball Screws provide an efficient, cost-effective linear motion solution in a small package....