Specialized Linear Motion Design

Unmatched accessibility, flexibility, and capability.

The Complete Package of Technical Support

Nook understands that each project and company can have different requirements. That's why we strive to be flexible in delivering the right level of support most appropriate for each individual project. Our team of proven, highly experienced engineers (many with 20+ years in the industry) has deep linear motion technology expertise. They can tailor a perfect solution to best fit your specifications, budget, and schedule.

Need a custom linear motion solution?

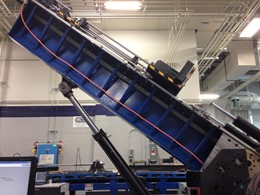

The toughest motion control and automation problems usually require some custom design engineering work. Our engineers have been designing customized solutions for decades. Chances are, we may have already developed a similar solution that may fit your application.

- Custom Design. We design and build linear motion components and subsystems that help machine developers save money while speeding time to market. Delivered as turnkey solutions, these components and systems are easily integrated into wide array of OEM machines.

- Build To Print. We can build, test, and even ship it with your personal markings and appearance. Our engineering services team routinely designs and builds private label finished products for aerospace, defense, semiconductor, and biomedical customers.

Streamline Your Design Process

We apply solid modeling and finite-element analysis (FEA), as well as industry best practices such as tolerance analysis, risk analysis, and comprehensive testing protocols to ensure all products perform to exact requirements. Design and process verification/validation tools are employed throughout the product development cycle.

Life testing with predictive tools, data for prognostics, performance wear models, and proof testing under multiple operating conditions helps to reduce design cycles.

Tools & Testing

- Engineering Analysis and Predictive Tools

- CTQ/KPV Engineering Specification Process

- Design and Test for Fault Tolerance and Prognostics

- FEA (Finite Element Analysis)

- DVP&R (Design Verification Plan & Report)

- Process validation to 21 CFR Part 82 (Medical Device)

- Reliability, DVP&R, Overload/Proof End of Line, Certification

Have a new and unique application?

Nook has a highly specialized team of application engineers dedicated just to working with customers on their specific applications. This team is highly experienced in solving unique challenges that other suppliers may not be able to support. We are committed to optimizing your machine by providing whatever you need including quotes, drawings, life calculations, models, and much more.

This provides you with more external resources for your project as well as saving you time for your product development. We are always ready and willing to assist you.

- We can proactively anticipate your needs as a trusted partner to get your project into motion.

- Give us your toughest linear motion application and let us solve your problems.

Project Support

Get better products to market faster

For over 50 years and several thousand successful projects, Nook has refined our process by combining established techniques with proven solutions and experienced staff to develop precision, cost effective, high performance motion systems that help our customers efficiently achieve performance and reliability goals while minimizing cost and cycle time.

Nook engineers start every project with a formal review to define objectives, specifications, and deliverables. In addition, we apply best practice project management to develop a detailed project plans, including budget and schedule.

Engineering services for all project phases:

- Project Planning

- Preliminary Design

- Detailed Design

- Prototyping

- Production

Design for Manufacturing

Engineering doesn’t stop with design. Nook has a fully integrated manufacturing facility (all operations under one roof). This allows us to tightly control and coordinate all aspects of new product development and implementation including design, manufacturing and supply chain, and quality.

Tight collaboration between design engineers, quality engineers, and manufacturing engineers facilitates strong Design for Manufacturing, Quality, and Reliability. This factors right into our customers' bottom line by minimizing development, operational, and implementation costs.

- Statistical Process Control (SPC)

- Design for Six Sigma Manufacturing

- DFMEA, PFEMA

- APQP (Advanced Product Quality Planning) Launch Protocols

- D.O.E. (Design of Experiments)

Protect your Development

Nook understands that your intellectual property (IP) is one of your most valuable assets. We have procedures built around safeguarding your IP including two-way nondisclosure agreements (NDAs), controlled design areas, and specialized "Blue Book" part numbers that protect your proprietary designs.