Military & Defense

Over 50 years as a trusted partner for providing innovative, rugged, and reliable motion solutions that perform in the most extreme environments.

Proven Design Support

As a manufacturer with 50+ years of experience, Nook continues to serve the Defense market as a trusted and responsive partner. We deliver innovative linear motion systems that perform with confidence when everything is on the line. Our highly experienced and accessible linear motion design experts support your mission critical projects from concept through deployment.

Rigorous Process Control

All Nook operations are co-located in one U.S. based facility allowing us to quickly adapt while maintaining rigorous process control over our entire supply chain. Our tightly controlled process integrity includes Lean Manufacturing, 5S, and Six Sigma. Our Quality systems emphasize continuous improvement, statistical methods and ongoing training.

Specialized Quality Systems

Proven systems to support the stringent requirements for aerospace, defense, and medical applications assures Nook as highly trusted partner.

- ISO:9001 Certified

- 9100:16 Certified

- ITAR Registered

Government Contract Specialists

At Nook, we have dedicated engineering resources that specialize in supporting government contracts. These highly experienced engineers have extensive experience in managing government Aerospace & Defense projects. We can help you navigate this challenging process.

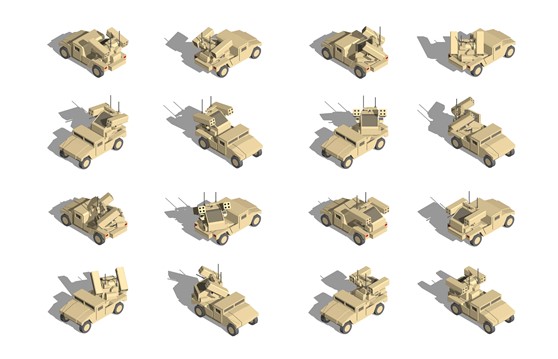

Specialized Vehicles

Smooth and Dependable Performance for Mission Critical Systems

Why risk the safety of your troops to inferior designs? All Nook components are made in the U.S. with all operations under one roof. This allows for very tight control over materials and processes. For over 50 years Nook has delivered several smooth operating, rugged, and customized solutions to several leading Mobile Off Highway contractors. Nook solutions are always ready for quick deployment to adapt readily to the evolving needs of the military & defense market.

- Armor Actuation

- Vehicle Sub-Systems (Brakes, Suspension, Engine)

- Seat Actuation

- Communications Satellites

- Trailer Hitches

- Cargo Handling

- Utility Actuation

- Door/Hatch Actuation

- Lift Mechanisms

- Robotics

Applications

- Armored fighting vehicles

- Reconnaissance vehicles

- Military light utility vehicles

- Combat Engineering vehicles

- Self-Propelled Anti-Aircraft Guns (SPAAGs) / Self-Propelled Air Defense Systems (SPADS)

- Military ambulances

- Electronic warfare vehicles

- Light rail vehicles

- Armored trains

- Amphibious vehicles

- Joint Light Tactical Vehicles

Missiles & Guided Munitions

For optimal lift, guided munitions applications require fast, precise, synchronized operation during launch and flight.

Nook products deliver positioning accuracy and high load capability which are key factors for applications for the smart weapons market. These include low cost, autonomously controlled, adverse weather devices for bombs and missiles. Nook ball screw systems provide highly accurate repeatability along any given position along the stroke.

Advantages Include

- Optimal Efficiency

- Low Power Requirements

- Compact Design

- Low Weight

- Ease of Synchronization

- Easily Adjusted Under Varying Loads

- Precise Ability to Repeat

Applications

Compact and Low Weight.

Nook products are an integral part of gun and linkless ammunition feed systems because they are compact, low weight, economic extremely and reliable. They are ideally suited for the highest speed firing mechanisms.

- Air-to-air Missiles

- Interceptors

- Surface-to-air Missiles

- Ship Borne Missiles

Communications

Nook products are ideally suited for customers within the communications industry. This primarily includes manufacturers of broadcasting and other wireless communications equipment.

Barriers

Nook jack systems are ideal for raising and and lowering cylindrical wedge barriers. These mechanical systems eliminate noisy and inconsistent hydraulic cylinders and pumps that can leak and require frequent maintenance. Nook systems provide a cleaner, quieter solution with reduced maintenance while operating in harsh weather extremes.

Application Benefits:

- Eliminates costly and complex hydraulic systems

- Environmentally friendly design - no contaminants

- Reduced noise levels

- Limited maintenance

- Reliable operation in extreme environments

Miniature Ball Screws: Big Efficiency in a Small Package

Miniature Metric Precision Ball Screws Miniature Metric Precision Ball Screws provide an efficient, cost-effective linear motion solution in a small package....