Integrated Stepper

Integrated stepper motors have a motion control component combined with built-in index feedback allowing for two-phase stepping with a high performance drive and 1000 line mapping encoder. These features offer a closed-loop, cost effective means to control a Nook mechanical solution.

INTEGRATED STEP-SERV MOTOR/DRIVE/ENCODER

This new integrated stepper system is a compact, cost effective drive-plus-motor-with-feedback package. The 2-phase NEMA 23 step motor is integrated with an advanced DSP stepper drive and a magnetic encoder to save you space, time and money. Competitive products are called “easy” servo or “hybrid” servo, Nook offers this step motor/drive with feedback which we describe as Step-Serv. Bonus: servo-tuning is not necessary, and a stepper does not “hunt” at rest like a conventional servo.

- A step/servo is an integrated motor, a complete brushless closed loop stepper system

- Closed-loop controls eliminate wiring, labor costs, and compatibility issues

- Integration yields compact size and reduced electrical interference

- 1000-line optical encoder position control

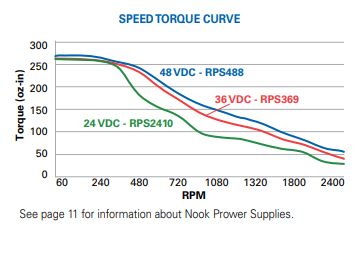

- High starting torque and quick response, smooth low speed motor movement

- Excellent response time, torque (30% over open loop)

- Load-dependent dynamic tuning keeps motor cool

- 2 N·m (285 oz-in) holding torque stepper motor

- Sixteen micro step resolution value from 200 to 51,200 steps per rev

- Isolated control inputs; no tuning for plug and play setup

- In-position and fault outputs to external motion controller

- Over voltage, over-current, and position-error protection