Ball Screw Thread Form Terms

Ball Screw Thread Form Terms

Introduction

Ball screws offer an efficient means of converting rotary motion to linear motion. A ball screw is an improvement over an acme screw just as an antifriction ball bearing is an improvement over a plain bushing.

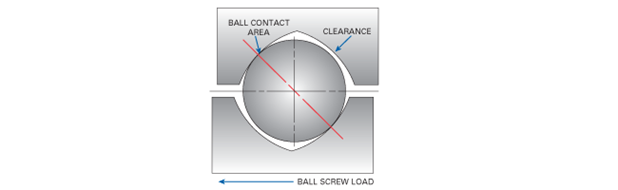

Ball screw assemblies have a number of bearing balls that transfer the load between the nut and screw. The thread form in which the bearing balls ride is an ogival shape formed from two arcs of the same radius with offset centers. This form is also referred to as a gothic arch.

Bearing Ball Circuit

The closed path that the bearing balls follow through the ball nut. Ball nuts have one or more circuits.

Return Guide

Component that allows the bearing ball to be picked up and returned to the beginning or end of the circuit.

Load Carrying Balls

The bearing balls in contact with ball nut and ball screw sharing the load.

Land Diameter

The outside diameter of the screw. This diameter is less than the ball circle diameter.

Ball Circle Diameter

The diameter of the circle generated by the center of the bearing balls when in contact with the screw and nut.

Root Diameter

The diameter of the screw measured at the bottom of the thread. This is the diameter used for column strength, critical speed calculations and end machining considerations.

Pitch

The axial distance between threads. Pitch is equal to the lead in a single start screw.

Lead

The axial distance the nut advances in one revolution of the screw. The lead is equal to the pitch times the number of starts.

PITCH × STARTS = LEAD

Screw Starts

The number of independent threads on the screw shaft; typically one, two or four.

Lead Accuracy

Lead accuracy is the difference between the actual distance traveled versus the theoretical distance traveled based on lead. For example: A screw with a .5 inch lead and ±.001 in/ft lead accuracy rotated 24 times theoretically moves the nut 12 inches.

24 Revolutions × .500 inches per revolution = 12.000 inches of travel with a Lead accuracy of .001 inch per foot, actual travel could be from 11.999 to 12.001 inches.

PowerTrac™ SRT Ball Screws will not deviate from nominal lead by more than ±.004 inch/foot on screws through 21/2" diameter and ±.008 in/ft on screws 3" and over. Details on page 96.

PowerTrac™ XPR Ball Screws will not deviate from nominal lead by more than ±.001 inch/foot. Details on page 122.

PowerTrac™ SGT Ball Screws will not deviate from nominal lead by more than ±.0005 inch/foot. Details on page 136.

Matched Lead

When multiple screws are used to move a load with precise synchronicity, screws of similar lead accuracy can be factory selected and supplied as sets. Consult factory for matched lead set tolerances.

|

Screw Type |

Material |

Surface |

Lead Accuracy |

Screw Dia. |

Screw Lengths |

|

SRT |

Alloy |

black |

±.004 in/ft |

0.375" to 6.000" |

up to 24' |

|

|

Stainless |

polished |

±.004 in/ft |

0.375" to 1.000" |

up to 24' |

|

XPR |

Alloy |

polished |

±.001 in/ft |

0.631" to 2.250" |

up to 12' |

|

SGT |

Alloy |

polished |

±.0005 in/ft |

0.631" to 2.250" |

up to 10' |

Straightness

Although PowerTrac™ Ball Screws are manufactured from straight, cylindrical material, internal stresses may cause the material to bend or yield. When ordering random lengths or cut material without end machining, straightening is recommended.

Handling or machining of screws can also cause the material to bend or yield. Before, during and after machining, additional straightening is required. When ordering screws with machined ends from Nook Industries, the following straightness tolerances can be expected:

PowerTrac™ SRT and XPR Ball Screws are straight within .010 inch/foot when shipped from the factory, and do not exceed .030 inch in any 6 foot section.

PowerTrac™ SGT Ball Screws are straight within .001 inch/foot when shipped from the factory.

Life

A ball screw assembly uses rolling elements to carry a load similar to an anti-friction (ball) bearing. These elements do not wear during normal use, but rather fatigue. Therefore, ball screw life is predictable and is determined by calculating the fatigue failure of the components.

Proper lubrication, regular maintenance, and operation within specified limits will allow PowerTrac™ Ball Screws to operate to the predicted life.

Efficiency

The low coefficient of friction of the rolling elements of PowerTrac™ Ball Screws and Nuts results in an operating efficiency greater than 90%.

Backdriving

Normally, ball screws are used to convert rotary motion into linear motion. Backdriving is the result of the load pushing axially on the screw or nut to create rotary motion.

All ball screws, due to their high efficiency, will backdrive. The resulting torque is known as "backdriving torque" and is the torque required to hold a load in position.

CAUTION: When using ball screws, applications should be analyzed to determine the necessity of a brake, especially when the possibility of injury may occur

Backlash

Backlash (lash) is the relative axial movement between a screw and nut without rotation of the screw or nut. The axial movement between a new PowerTrac™ SBN or SGN ball nut and screw will range from .003" to .015" depending on size. Lash in ball screws will remain constant during normal use.

Selective Fit

When less than standard lash (listed above) is desired, SBN and SGN ball nuts can be custom-fit to a specific screw with selected bearing balls to minimize lash to .003" to .005" depending on ball size. Select fitting may result in lower life.