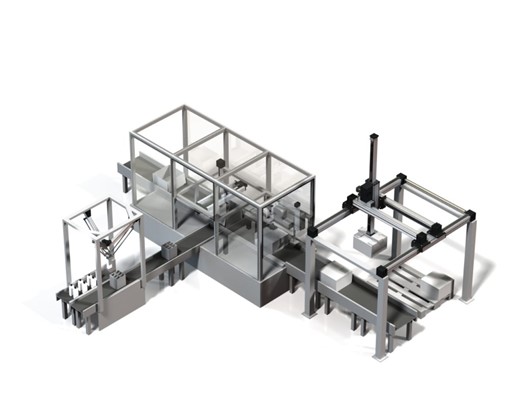

Packaging

Nook products and services provide fast, reliable, and highly accurate solutions with perfect combination of performance, life and cost required by packaging applications.

Fast cycle times and high productivity secure the competitive advantage.

No other industry is so centered around cycle times as packaging technology. Plants are must be extremely flexible to handle many different types of boxes and containers as possible on one machine, in the same work flow. Also, performance and reliability are critical components in packaging machinery.

Conversion times are best optimized with a fully automated format. The degree of automation in packaging technology is correspondingly high, and is continuing to increase due to the trend for customized packaging.

Advantages

- Compact Design

- Long Service Life and Excellent Reliability

- High Load Capacity and Bearing Load

- Unlimited Customization

- Resistant to Difficult Environments (dust or abrasive materials)

Nook provides customized linear motion solutions that offer a high level of safety, flexibility, and precision.

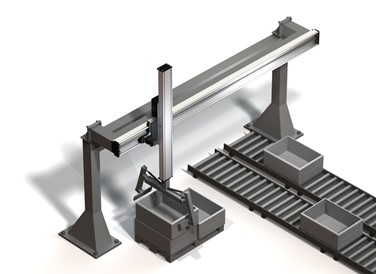

Palletizing

Position Heavy Loads at High Speeds.

Palettizing systems with integrated handling create automated systems that are gentle on parts for optimum quality. These systems must execute linear movements precisely and reliably. In addition, they need to be space-saving and easy to integrate into existing structures. A high degree of flexibility is therefore vital. We supply linear axes and multi-axis systems that perfectly meet these requirements.

Nook adapts the drive units to the exact needs of an application to save space. The modular construction provides flexibility without compromising standardization. This versatility seamlessly combines linear axes that are designed and dimensioned perfectly – up to the exact length.

Handling portals and palletizers are at the beginning and end of numerous production processes. The demands in terms of availability and service life are correspondingly high. Nook linear axes are designed to be highly robust and are customized to the specific task on site.

Applications

- Stacking

- Picking

- Unstacking

- Clearing

- Positioning

- Centering

Here’s another design detail: Nook linear axes are statically optimized to meet the application requirements. It is particularly important in portal systems to keep an eye on bending forces. Thus, the extruded aluminum profiles for Y and X axes are also self-supporting over longer distances without additional support points.

Articulating robot arms are commonly used, but due to their large structural mass, they have limits to how fast they can process product into the correct position. The use of a Nook three-axis gantry can realize a significant increase in production output without damaging the product. With the utilization of planetary gearboxes, servo motors and drives, a gantry system allows end users to modify the pallet stacking sequence without mechanical and software changes.

Advantages

- Unlimited Customization

- High Speed and Acceleration

- Trouble-free Operation

- Optimal Throughput

- Maximum Precision

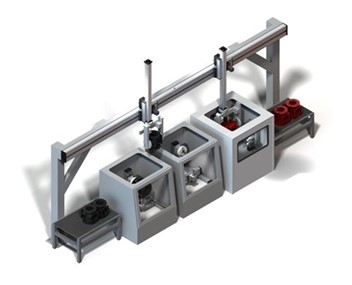

Box Forming & Wrapping

Capable of handling a variety of box forming requirements.

Nook products increase forming speeds while delivering longer cylinder life and the vertical thrust required to form trays and boxes from blank corrugated board stock This reduces changeover time between carton and/or box sizes while increased forming speeds for excellent throughput.

Boxes and/or cases come in many shapes, sizes and styles, so box forming equipment must be capable of handling a variety of box forming requirements.

Typical Applications

- Box Loading - Typically includes robotics and push bar.

- Box Closing (gluing, tape, sealing)

- Robotics - Equipped with special end of arm tooling to lift a finished roll from an accumulation conveyor and load it into a box (utilizes RFID technology).

- Double Rolls - Two rolls are positioned side by side before being pushed into an open box. The flattened boxes are automatically pulled out of the magazine, and formed into an open case.

Nook linear motion solutions provide simple, high quality systems that can be built from standard components providing long life, and virtually no maintenance. Scalable cost is illustrated in single axis motion systems for stretch wrapping applications.

Packaging systems must ensure the quality of primary, secondary and final packaging while at the same time maximizing production flow. These systems are commonly used throughout automated packaging applications to monitor, track, and trace critical data to ensure quality while maximizing productivity.

Carton Packing, Filling, Measuring

A wide range of tasks with minimal changeover.

Carton packing applications can have special needs that are best realized with a combination of standard and customized mechanical components. The right mix of linear motion components enables filling machines the flexibility to handle a wide range of tasks with minimal changeover. Fully enclosed linear systems keep contaminants out of the mechanisms and also eliminate risk of contaminating the filling process.

Packaging machine builders require higher speed machines for packaging and carton staging system to keep up with the higher speed of the modern machines. Because of the speed and precision required, consistent position repeatability and precise positioning accuracy are crucial.

Printing & Scanning

Nook provides the accuracy, high speed and flexibility with minimal engineering effort for printing, labeling and scanning operations. This includes gantry systems with linear guide and ball screw components utilized on conveyors with visual recognition systems that transport items of varying size for printing (or scanning) while in motion.

3D printing is ideal when conventional manufacturing has reached its limits. These manufacturing processes are often used in prototype construction, for components with a high degree of customization, and with complicated geometries. Linear axis systems are an essential feature in 3D printers. They position the laser head in the portal group and feed in material layer by layer. Nook linear axes are used in a challenging environments that call for a high level of positioning and repeatability in non-stop, 24/7 operations.

Linear Actuators for Automated Packaging

Click here to view...

Selecting Linear Actuators for Robotics

Click here to view...