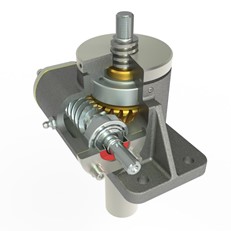

Screw Jack

ActionJac™ Worm Gear Screw Jack systems are ruggedly designed and produced in standard models with load handling capacities from 1/4 ton to 100 tons. Metric capacities are also available from 5 kN to 200 kN.

- No "standard" travel lengths (built to specification).

- Ductile iron housings proportioned to support the rated capacity of the unit.

- Use individually or in multiple screw jack arrangements.

- Alloy steel worm drive with high strength bronze worm gear (drive sleeve).

- Anti-friction tapered roller bearings with external seals to prevent loss of lubrication.

- The drive sleeve is supported on anti-friction tapered roller or ball thrust bearings.

- Premium finishes are available including Epoxy, Outdoor, Marine, or per customer specification.

Rugged and Reliable Screw Jacks

Selecting the Proper Screw Jack

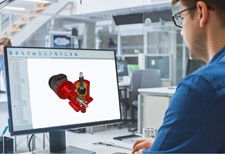

Design Guide Pro Product Selectors

Design your own screw jack system with the easy to use DESIGN GUIDE PRO tools. Enter your specific parameters to design the ideal linear motion solution based on your individual application.

3 Quick Screw Jack Applications - Food Industry

In the food sector, screw jack systems are typically deployed in three common and versatile arrangements. Let's talk about a few of these in more detail....

Screw Jacks and Environmental Applications

A screw jack application operating condition is defined by two criteria. The first is the environment and the second is the temperature. The environment describes the area where the screw jack application is located. The temperature describes the ambient temperature in which the screw jack will be performing....

8 Design Considerations for Screw Jack Systems

Regardless of the type of worm gear jack you are considering (machine screw or ball screw), there are 8 factors that are critical for developing the optimal linear motion system....

Faster Delivery for 2.5 & 5 Ton Jacks

2 Week Delivery for Standard 2.5 & 5 Ton Jacks3 Week delivery was good... but not good enough for the Nook Manufacturing Team. Motivated by the increased need for faster delivery, Nook can now provide...

Anode Screw Jacks for Aluminum Smelting

Nook can provide customized anode screw jack solutions to aluminum smelters that are seeking to replace older obsolete/failing systems. We can readily provide new, cutting edge anode screw jack designs to upgrade these facilities while significantly improving the efficiency and throughput of the overall smelting process.