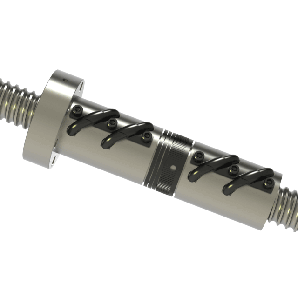

PowerTrac 2250 - 0500 SGT RA, with SAG Ball Nut, Adjustable Preloaded

Inch Ball Screw AssemblyPrecision Ground Inch Ball Screw, SGT, 2.250" Ball Circle Diameter, 0.500" Lead, RH Thread, Inch Ball Nut, for SGT, Ground Accuracy, Preloaded, Adjustable, SAG, Flanged

Read More

Product Specifications

Product Specifications

Configure

Product Specifications

Inch Ball Screw

(Screw)Product Info

- Screw Code:

- 2250-0500 SGT RA

- Precision:

- SGT

- Screw Material:

- 4150

- Thread Direction:

- RH

(Screw)Details

- Ball Circle Diameter [in]:

- 2.250

- Lead [in]:

- 0.500

- Root Diameter [in]:

- 1.850

- End Code for Types 1,2,3,5 [* Journals may show tracings of the thread]:

- 25

- End Code for Type 4 [* Journals may show tracings of the thread]:

- 28

(Screw)Performance Specifications

- Lead Accuracy +/- [in./ft.]:

- 0.0005

(Screw)Part Numbers

- 2 ft. Part Number:

- 4 ft. Part Number:

- 6 ft. Part Number:

- GT22550R72

- 8 ft. Part Number:

- 12 ft. Part Number:

- 16 ft. Part Number:

- 20 ft. Part Number:

(Screw)Weight

- Screw Weight [lb./ft.]:

- 10.80

Inch Ball Nut, for SGT, Ground Accuracy, Preloaded, Adjustable, SAG

(Nut)Product Info

- Ball Nut Number:

- SAG0706

- Thread Direction:

- RH

(Nut)Details

- Ball Circle Diameter [in]:

- 2.250

- Lead [in]:

- 0.500

- Nominal Ball Diameter [in]:

- 0.375

- Root diameter [in]:

- 1.850

(Nut)Forces and Torques

- Torque to Raise 1 lb. [in-lb]:

- 0.088

(Nut)Flange Part Numbers

- Flange Part Number:

- INCLUDED

(Nut)Wiper Part Numbers

- Wiper Kit Part Number:

- BRUSH

(Nut)Weight

- Nut Weight [lb]:

- 24.20

(Nut)Performance Specifications

- Maximum Adjustable Preload [lb]:

- 6390

- Spring Rate x 106 [lb./in.]:

- Dynamic Load [lb]:

- 30000

- Static Load [lb]:

- 142660

More Details

To obtain optimum performance of Nook precision ball screws, it is required that the ball screws machined in their case hardened state. When annealing is applied to the end of the ball screw for machining purposes, the lead accuracy is distorted causing the ball nut to lock or jam on the ball screw.

Nook precision ball screw and nut assemblies provide ease of application without the need to machine or anneal the ball screw, as all that is required is installation. Nook precision assemblies offer turnkey solutions that only require a power source (hand operation or motor). All of the elements are available for quick delivery from shelf stock.