Specialized Testing & Analysis

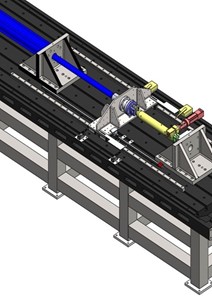

Nook Industries has the ability to Evaluate, Optimize, and Validate your custom linear design.

Nook provides a wide variety of testing and simulation services to help our customers design better products. We can simulate many real-world scenarios to determine how a given design will perform. This helps to speed design process, improve reliability, determine life cycle, and predict performance in advance.

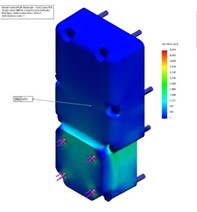

We apply solid modeling and finite-element analysis (FEA), as well as industry best practices such as tolerance analysis, risk analysis, and comprehensive testing protocols to ensure all products perform to exact requirements. Design and process verification/validation tools are employed throughout the product development cycle.

Nook's engineering team is trained and experienced in designing and evaluating solutions for some of the harshest conditions across multiple industries, including Nuclear, Defense, and Aerospace.

Design Optimization and Validation

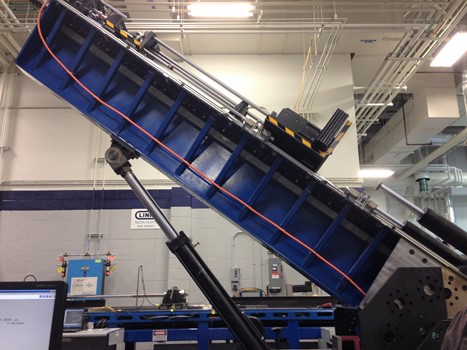

Life testing with predictive tools, data for prognostics, performance wear models, and proof testing under multiple operating conditions helps to reduce design cycles.

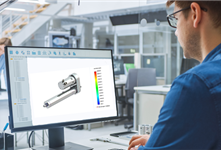

Nook utilizes traditional calculations paired with Solidworks™ Simulation to perform upfront component and system evaluation. This allows the design to be optimized before parts are released for manufacturing. Ultimately, this predictive modeling helps to avoid costly design issues from appearing further into the program schedule.

Design Validation Testing

- Life Testing

- Loading Testing

- Efficiency Testing

- Functional Testing

Simulation

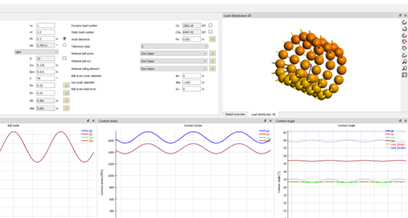

Other simulation software such as MESYS is utilized to optimize ball screw performance. The Nook engineering team can evaluate and optimize performance from the total system down to the individual ball bearing used.

- Linear Static Analysis

- Nonlinear Static Analysis

- Frequency Analysis

- Thermal Analysis

- Random Vibration Analysis

- Nonlinear Dynamic Analysis: impact, shock, time

- Varying Loads

- Design Study (Parametric Optimization)

- Fatigue Analysis

- Linear Buckling Analysis

- Drop-Test Analysis

Nook Industries can see a design through from initial design optimization to final design validation based on the customer's individual needs. From efficiency testing to life validation, we can design, test, and validate linear motion systems from beginning of the development cycle to product release.

Analysis

- Life Analysis

- Loading Analysis

- Structural Analysis

- Efficiency Analysis

- Critical Speed Analysis

- Load distribution between rolling elements

- Reaction forces/moments and displacements/rotations

- Contact pressure for each contact

- Contact angle according to axial position of the ball