Packing a Punch for Packaging Automation.

In my latest blog posts, I've been trying to focus on rapidly evolving industries. The Packaging industry has historically been constantly evolving. However, unlike other upstream production processes, it has typically lagged in automation technology. But that is quickly changing as new technology advances become available that continue to lower the costs of implementing such systems.

The advent of newer sensors, human-machine interfaces (HMIs) and motion controls are increasing the capabilities of packaging automation more than ever. One of the key challenges for automated packaging technology is the ever-increasing need to run multiple different programs for several different products on a single platform (while optimizing cost and floor space). In addition, there is surely no other industry that is so centered around cycle times as the packaging industry.

When it comes to faster cycle times, a fully automated system is the best choice for increasing speed and eliminating errors. We are seeing significantly more interest in customized automated packaging solutions across virtually every industry.

Packaging Line (multiple operations)

Improving Process Control with Electric Linear Actuators

Electric linear actuators are perfect for optimizing the packaging stages of the manufacturing process. Packaging operations pose their own unique challenges. For example, packaging multiple products together on the same machine requires tight synchronization to sort and organize them before placing them into final cartons (with fast throughput and no errors).

Linear actuators are crucial to increasing the efficiency of rapid changeover in an automated packaging process. This is because they can easily be adjusted through software and firmware in order to increase the utilization of a given packaging machine. In addition, they operate with stunning precision of movement and control to virtually eliminate errors.

Precise motion and speed are important, however, there are other key factors to consider as well such as safety and quality. Electric linear actuators are ideally suited to act as a braking mechanism if a fault occurs. This allows the machine to stop as quickly as possible to avoid damaging people or products. With electronics and linear actuators, feedback loops are continuously monitored for proper functionality. Adjustments are automatically made to align the process as needed).

Electric linear motion control is increasingly being used for packaging steps that have traditionally relied on pneumatic and hydraulic technologies. A good example includes automated robotic palletizing equipment that can seamlessly synchronize multiple process steps with electric linear actuators.

Key Advantages of Electric Linear Actuators:

- Increased Productivity

- Reduced Scrap

- Consume Less Space

- Low Noise

- Increased Flexibility

- Controlling multiple setups

- Excellent Transfer Speed

Explore Packaging Applications

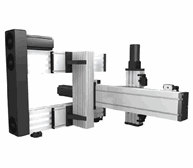

Modular Linear Actuators for Automated Packaging

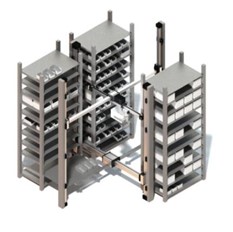

Modular Linear Actuators operate very smoothly allowing an automated processes to gently handle parts without damaging them. These linear actuator systems carry out movements precisely and reliably while minimizing shop floor footprint space. Because they are extremely configurable, they easily adapt to various product packaging requirements on a single assembly line. In addition, modular linear actuators also integrate easily into existing facility structures.

These linear motion devices are highly effective in carrying out a multitude of packaging operations including:

- Stacking and Un-Stacking

- Picking

- Clearing

- Positioning and Aligning

- Sorting

Modular linear actuators adapt to the exact needs of an application while integrating into the existing machine design and footprint - saving space while adding simplicity and increasing flexibility. The modular construction provides the required flexibility without compromising on standardization. This versatility makes it possible to seamlessly combine unique linear axes for a perfect fit - up to the exact length needed. The linear actuators adapt to the machine design (and not vice-versa).

Watch Video Demonstration:

https://www.youtube.com/watch?v=uyOQbQcyvqc

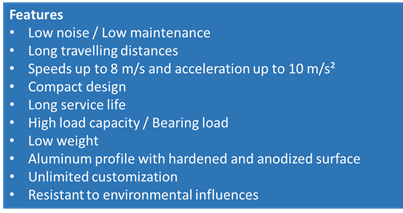

Warehouse Picking System

Programmable Linear Actuators for Automated Packaging

Programmable Linear Actuators are ruggedly designed for continuous duty, larger loads, long service life with higher speeds. They incorporate a direct drive or toothed belt drive for high mechanical efficiency that allows for a quiet running performance. Programmable actuators are supplied with either a ball screw or acme screw, and either a servo or stepper drive system.

These devices provide a complete system including motor, drive, controller, and power supply. This makes programmable linear actuators ideal for packaging motion control situations. They are easily programmed to handle multiple different packaging product operations.

In addition, they can be equipped with a wide variety of sensing devices and accessories to control any packaging application.

Want to improve the process control of your automated packaging application?

Modular Linear Actuators

Modular Linear Actuators