Medical & Diagnostics

Nook products are produced with rigorously controlled manufacturing processes and stringent quality standards making them an ideal fit for medical applications.

Proven Design Support

Leverage Nook early in the design phase to shorten your launch cycle.

For decades, Nook has optimized the linear motion of countless medical equipment designs. This expertise provides your design team with increased flexibility, performance, and confidence.

Our seasoned medical motion experts are always ready to assist in your next design process. Let us optimize your machine performance, life cycle, and budget with unmatched capabilities for analysis, testing, and validation.

Rigorous Process Control

This is the Nook advantage.

All Nook operations are co-located in one U.S. based facility allowing us to quickly adapt while maintaining rigorous process control over our entire supply chain. Our tightly controlled process integrity includes Lean Manufacturing, 5S, and Six Sigma.

Leverage our unparalleled ability to control all design, sourcing, manufacturing, and analysis.

Specialized Quality Systems

Nook Quality systems emphasize continuous improvement, statistical methods and ongoing training.

Our proven linear technology, superior components, and tight process control deliver unmatched efficiency, durability, repeatability, accuracy, and low noise performance that you and your patients can trust.

- ISO:9001 Certified

- 9100:16 Certified

- ITAR Registered

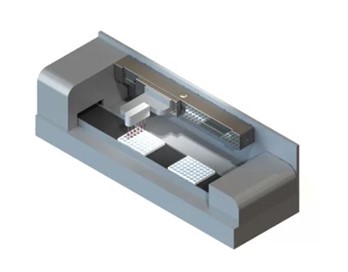

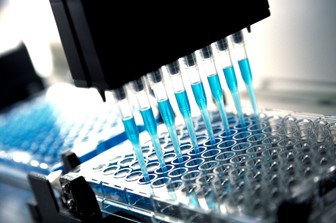

Laboratory Automation

Customized solutions of the highest quality and precision.

Laboratory automation researches, develops, and optimizes technologies that enable new and improved processes to increase productivity, elevate data quality, and reduce cycle times. Today's laboratories must achieve timely results to remain competitive.

Equipment used for clinical diagnostics, medical research, treatment, and pharmaceutical must meet the highest quality and safety standards over the complete life cycle of the product. And that’s exactly what Nook provides. Our ball screw assemblies and linear actuator products are manufactured under strictly controlled conditions that conform to the applicable standards.

Applications

Nook automated linear motion solutions optimize laboratory automation operations with reduced costs, increased efficiency, consistent performance, and minimal downtime. Our ball screws and linear actuator products are ideal for automated or robotic pick & place workstations where accurate positioning and smooth operation at higher speeds are critical factors.

- High-throughput screening

- Combinatorial chemistry

- Automated clinical and analytical testing

- Diagnostics

- Laboratory Robotics

Medical Devices

Repeatability and Accuracy for Reliable Treatment.

Medical devices benefit patients by helping health care providers diagnose and treat patients, helping them to overcome sickness and improve lives. Medical devices must be proven safe and effective with reasonable assurance before regulating governments approve them for use.

Over the last several decades, Nook ball screw assemblies and linear actuators have been fundamental to precision medical devices such as liquid dispensing, IV pumps, drug delivery and blood sampling. These products readily dispense and transport fluids with complete accuracy, repeatability, and smooth operating performance.

Applications

- Fluid Pumps

- Drug Delivery

- Infusion Pumps

- Adhesive Automation

- Automated Pipetting

- 3D Printing

- Medical Devices

Personal Mobility

Quiet, Safe, and Consistent Motion.

A plethora of Nook ball screw assemblies and linear actuators are routinely used to properly adjust personal mobility equipment and ergonomic positioning devices for maximum comfort. These devices must routinely perform in varying environmental conditions (indoor, outdoor, terrain). These products are ideal for personal mobility device adjustments that require quiet, safe, and consistent movements such as tilt, recline, head and leg positioning.

Advantages Include

- Transfer heavier loads (full patient weight) smoothly with minimal torque

- Less Power consumption with reduced effort on power source (minimize battery drain)

- Smooth and quiet operation

- Positive, stepless adjustment with precision ball screws

- Predictable and tightly controlled adjustment without sudden movement

Applications

- Wheelchairs and Accessories (Power and Manual)

- Power Scooters

- Vehicle Lifts & Vehicle Ramps

- Vehicle Controls (Throttle, Brakes)

- Ergonomic Positioning

- Seating, Transfer and Storage

- Stair Lifts

- Accessible Vehicles

Patient Handling

Quiet, Vibration-free, Ultra-dependable.

Nook’s quiet, vibration-free, ultra-dependable ball screw and linear actuator products enable safe, easy, and precise equipment adjustment to accommodate the individual needs of patients. This includes vertical, horizontal, and back and forth motions. These proven medical solutions deliver positioning accuracy and high load capability which are key factors for applications such as surgical and MRI machine tables. Applications such as patient lifts, dental chairs, and patient transfer devices demand smooth, quiet operation for patient comfort, ergonomics, safety, and ease of use.

Advantages Include

- Transfer heavier loads (full patient weight) smoothly with minimal torque

- Less Power consumption with reduced effort on power source (minimize battery drain)

- Smooth and quiet operation

- Positive, stepless adjustment with precision ball screws

- Predictable and tightly controlled adjustment without sudden movements (Very Safe)

Applications

- Tables, Surgical Tables

- Chairs, Dental Chairs

- Stair Lifts, Bed Lifts, Bath Lifts

- Ambulance Transfer Devices

- Patient Furniture

Medical Motion: Precision Ball Screw Technologies

Click here to view...

Miniature Ball Screws: Big Efficiency in a Small Package

Miniature Metric Precision Ball Screws Miniature Metric Precision Ball Screws provide an efficient, cost-effective linear motion solution in a small package....

Optimizing Diagnostic Laboratory Throughput

Medical laboratory automation has always been a great fit for the linear motion industry. However, in a post COVID-19 pandemic landscape, linear motion devices such as precision ball screws and...