Planetary Roller Screw Products

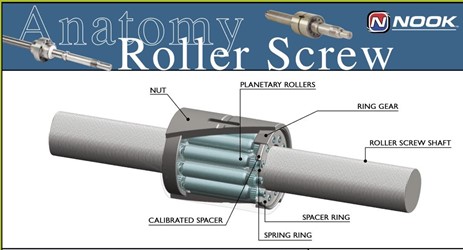

Nook Planetary Roller Screws (NRS), a member of the lead screw family, are remarkable devices designed to convert rotary motion into axial force or vice versa. They offer multiple advantages and reliability for the most demanding applications.

Roller Screw Advantages

- Highest efficiency rolling motion (even in shallow lead designs)

- Multiple contact points that carry large loads with very high resolution

- Small axial movement (even with very shallow leads)

- High rotational speeds with faster acceleration (no adverse effects)

- The most reliable screw solution available

- Higher cost option with highest performance

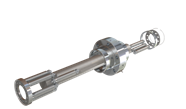

Nook Precision Roller Screw

Preloaded NRS

Split nuts installed with two halves pushed against each other and the clearance removed for preload. A large number of contacts and great rigidity eliminate requirements for high preload to perform backlash-free under most conditions. They only carry load on a reduced length of thread (half-length minus the half-thickness of the calibrated spacer).

Non-Preloaded NRS

One-piece solid nuts do not have a calibrated spacer to remove backlash. One-piece nuts have larger load ratings since all threads of the nut can carry load.

NRS High Strength Materials

- Screw shaft is medium carbon induction hardened alloy steel.

- Rollers and nut are high-grade bearing steel.

- Rolling surfaces are heat treated to a surface hardness not less than 56 HRC with a case depth suitably chosen to carry the load. Other materials, such as stainless steel, can be provided upon request.

Reduced load ratings should be considered when designing stainless steel roller screws.

Roller Screw - Metric

NRS Roller Screw

The NRS design offers multiple advantages and reliability for the most demanding applications when compared with other lead screw types due to its rolling motion.

- High efficiency in relatively shallow lead designs.

- Multitude of contact points of the planetary rollers can carry large loads and provide very high resolution (small axial movement) when using very shallow leads.

- Produce high rotational speeds with faster acceleration without adverse effects.

SFZ Lock Nuts

SFZ Lock Nuts

Conventional locknuts may not be suitable in a typical roller screw application due to the high axial load generated. Nook series SFZ locknuts are designed to carry high axial forces while minimizing the rotational inertia, an important benefit in high dynamic applications.

- High axial load

- High loosening torque

- High accuracy optimizes load on the thread interface

Evolving Planetary Roller Screw Applications

This growth can be attributed to the increasing use of roller screws in electric aircrafts where they are used as actuators that convert the rotary motion of the aircraft into linear motion. Also,...