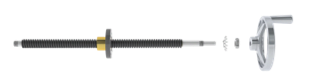

End Bearing Support

Linear motion applications utilizing a ball screw, or an acme screw require this screw end machining to be matched with precision bearing mounts. Nook offers both end bearing mounts and end machining as a complete assembly. End bearing mounts must be designed to withstand both the radial and the thrust loads generated by the application screw assembly.

- EZZE-MOUNT™ precision bearing blocks can be assembled to precision machined screws.

Add Motors or Hand Wheels

EZZE-MOUNT™ bearing mounts are available with integral motor mounts to offer complete motorized systems or manual hand wheels. Motor mounts are available for standard NEMA mounts (17, 23, 34, 42) as well as, IEC frames for servo and stepper motor applications.

Nook EZZE-Mount™

Bearing Support - Universal Standard

Universal Bearing Mounts

Available with double angular contact bearing or single radial bearing arrangements and can be mounted from either the front or back face, and the bottom surface (available with motor mounts).

Bearing Support - Universal Single

- Single Radial Bearing

- Type 1 Standard End

Bearing Support - Universal Double

- Double Angular Bearing

- Type 3 Standard End

Bearing Support - Universal Double (With Motor Mount)

- Double Angular Bearing

- Type 3 Standard End

Bearing Support - Universal Compact

Universal Compact Bearing Mounts

Bearing Support - Universal Single

- Single Redial Bearing

- Type 7 Standard End

Bearing Support - Universal Double

- Double Angular Contact Bearing

- Type 6 Standard End

Bearing Support - Flanged

Flanged Bearing Mounts

Available with double angular contact bearing or single radial bearing arrangements and are mounted using the back face and come with a machined piloted surface for ease of mounting and alignment (available with motor mounts).

Bearing Support - Flanged Single

- Single Radial Bearing

- Type 1 Standard End

Bearing Support - Flanged Double

- Double Angular Contact Bearing

- Type 3 Standard End

Bearing Support - Flanged Double (With Motor Mount)

- Double Angular Contact Bearing

- Type 3 Standard End

Bearing Support - High Capacity Fixed

High Capacity Fixed Bearing Mounts

Come with four angular contact bearing arrangement and are considered a fully ridged bearing and (used when a stiffer mounting surface is required). High Capacity Fixed Bearing Mounts are mounted using the back face and come with a machined piloted surface for ease of mounting and alignment.

- Four Angular Contact Bearings

- Used with Type 5 Standard Ends