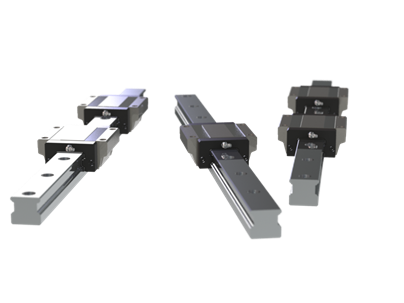

Profile Rail Systems and Runner Blocks

The compact design of Nook runner blocks offers greater design flexibility and several methods of mounting compared to other linear guidance systems. Special retainers and re-circulation tubes prevent balls from escaping when the runner block is removed from the rail.

Features And Benefits:

- Equal load carrying capacity in four directions with High Rigidity and Moment Rigidity.

- Steel bearing balls recirculate between the rail and the runner block and contact both surfaces at a 45 degree angle. Equal load can be applied bi-directionally in both horizontal and vertical axes.

- Full radius ball raceways circular shape provides ideal ball to ball raceway contact for increased rigidity. Also capable of withstanding moment loads.

- Precise geometry of ball raceway square configuration is ideal for preloading and high rigidity.

- A range of preloads are available depending upon rigidity and load capacity. Preload is achieved by the selection of precisely graded ball diameter.

Caged Profile Rail

The Caged Ball Chain Design provides lower friction and lower noise than traditional profile rail block designs. The benefit of a caged ball design prevents the bearings from incidental contact, which reduces friction, wear, and noise.

Rotational Ball Chain:

- Reduces noise

- Higher speed in motion

- Prolong service life

- Prolong re-lubrication period

A uniquely patented ball chain design provides a flexible link between the block and bearings. This gives the ball chain enough space to rotate and move in the circulation channel and overcome the friction of the curvature. In addition, the space between upper and bottom parts has oil storage functions, increasing the re-lubrication interval and service life.

Automation Series

The NARC linear guides provide 5 different classes of precision: N, H, P, SP, and UP class. Engineers can choose a different class depending on machine applications. Accuracy

Heavy Load Series

The NHRC is designed to accommodate high cycle demands and high speeds when they are required.

Non-Caged Profile Rail

Miniature Ball Profile Rail

EMBEDDED INVERSE HOOK DESIGN FOR REINFORCED MECHANICAL INTEGRATION

When the runner block is in motion and changing direction, the circulating stainless steel balls inside the raceway generate

impact force against the plastic end cap. As the demand for rapid motion in the automation industry has increased, Nook has

invented a new design to improve high speed running capability. Plastic inverse hooks for miniature linear blocks tightly secure

block components to handle the impact force effectively by distributing the applied stress over a large area.

UNIQUE BALL RE-CIRCULATION DESIGN

The stainless steel ball re-circulation hole and channel constructs are fully sealed by plastic frame and end caps. The simple

structure substantially reduces contact surface between steel ball and metal to sigificantly reduce noise. The lubrication

oil storage embedded in the circulation channel greatly extends the re-lubricating interval, extends life, and reduces

preventative maintenance.

Suitable for:

- High speed belt driven mechanism

- High speed carrier design

- Automation linkage between stations

NMR-EE SERIES STAINLESS STEEL REINFORCED PLATES ENSURE HIGH ROBUSTNESS

Runner blocks are equipped with two stainless steel plates which reinforce the end-cap from end to end. This sturdier design

supports higher running speeds. The plates can also function as scrapers to facilitate smooth travel.

Standard

The miniature linear guide series have three accuracy grades for design selection. Regardless of series, the NMR miniature linear guides use a stainless steel processed material. A lubrication storage design that is environmentally-friendly system, which requires less lubricant.

Wide

The wide miniature linear guide series has the same benefits as the standard miniature rail with the addition of a wider rail and block. This allows for a larger moment load and capacity for the same size rail.

Need Help Selecting Profile Rail?

Collaborate with one of our technical experts on the specifics of your application to ensure the ideal product fit that best meets your performance requirements and budget.