Belt Driven Modular Linear Actuators

Designed for high speeds with long distances. Perfect for fast positioning and handling tasks with low maintenance requirements.

Belt Driven Modular Actuators have a distinct advantage due to their ability to be manufactured in virtually any length. Belt drive actuators models include either an external, trapped, or internal belt arraignments. The Belts are made of a high tension steel material that only requires a single adjustment after initial use. No further tension is required. The pulleys have maintenance free ball bearings.

Available for clean room and explosion proof environments.

Excellent performance over long distances

High tension steel belt material

• Internal or external belt

• No minimum length

• Standard accuracy

• 0.1 mm repeatability

V Groove Guided

The carriage moves along the unit guided by V-slides that are adjustable to reduce lash. The linear opening of the unit is sealed with a stainless steel cover plate to make the unit splash-proof and dust-tight.

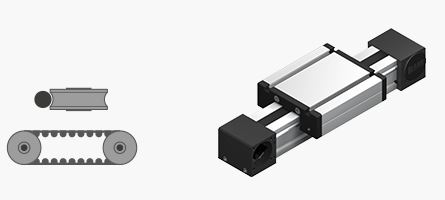

Internal Roller Bearing Guided

The carriage moves along the unit guided by hardened steel guide rods on the inside of the actuator that are adjustable to reduce lash. The linear opening of the unit is sealed with a stainless steel cover band to make the unit splash-proof and dust-tight.

External Roller Bearing Guided

The carriage moves along the unit guided by hardened steel guide rods on the outside of the actuator that are adjustable to reduce lash. The linear opening of the unit is sealed with a stainless steel cover band to make the unit splash-proof and dust-tight.

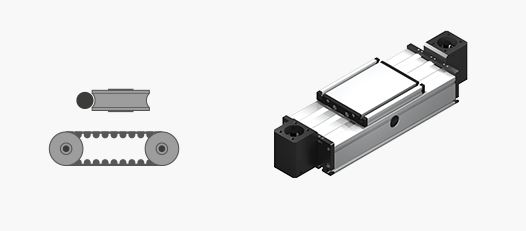

Internal Profile Rail Guided

The carriage moves along the unit guided by a single or dual internal profile rail on the outside of the actuator that are adjustable to reduce lash. The linear opening of the unit is sealed with a stainless steel cover band to make the unit splash-proof and dust-tight.

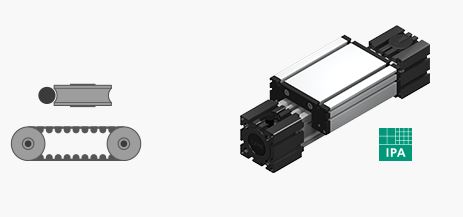

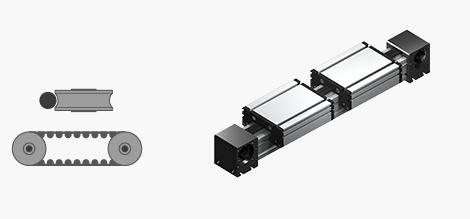

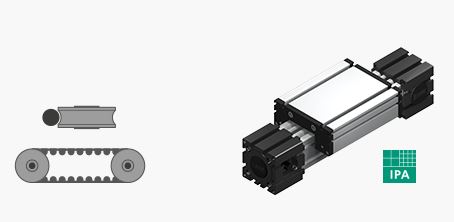

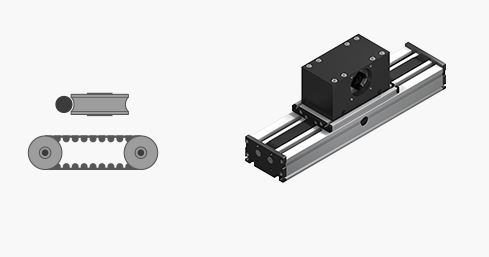

External Roller Bearing Guided

External Belt Driven

ELZ 30, 40, 60, 60S, 80, 80S, 100, 125

An aluminum square profile with integrated, hardened steel guide rods. The carriage, which has internal linear ball bearings that can be adjusted free of play, is driven along the guide rods by a timing belt. The pulleys have maintenance-free ball bearings. Belt tension can be readjusted by a simple screw adjustment device in the carriage. This device can also be used for symmetrical adjustment of two or more linear units running parallel.

- Fitting position: As required. Max. length 6,000 mm without joints.

- Carriage mounting: T-slots.

- Unit mounting: T-slots or tapped holes in the bearing block, mounting sets.

- Belt type: HTD with steel reinforcement, no backlash when changing direction, repeatability: ± 0.1 mm.

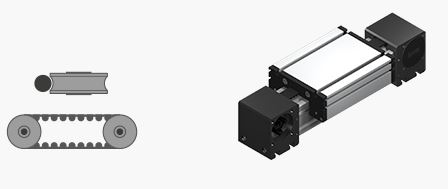

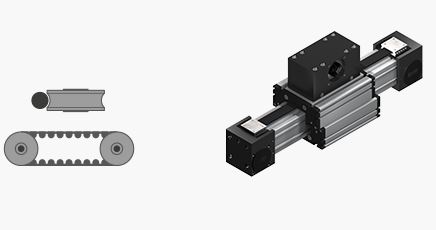

ELSZ 30, 40, 60, 60S, 80, 80S, 100, 125

An aluminum square profile with hardened steel guide rods. The carriage, which has internal linear ball bearings that can be adjusted free of play, is driven along the guide rods by a timing belt. The pulley has maintenance-free ball bearings. Belt tension can be readjusted by a simple device in one of the end blocks. This device can also be used for symmetrical adjustment of two or more linear units running parallel.

- Fitting position: As required. Max. length without joints 6,000 mm.

- Carriage mounting: T-slots.

- Unit mounting: T-slots, threads or tapped holes in the bearing blocks, or mounting sets.

- Belt type: HTD with steel reinforcement, no backlash when changing direction, repeatability ± 0.1 mm.

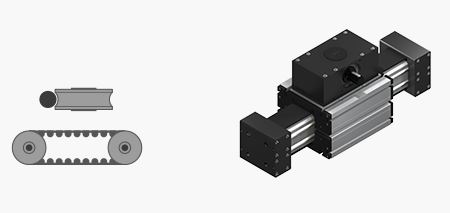

ELSD 40, 60, 60S, 80, 80S, 100

Same as ELSZ, but with an additional rotary shaft, fitted within the aluminum body. One end can be driven by any suitable motor, and the other end is provided with a shaft with feather key and an axial tapped hole for fitting grippers or other components.

- Fitting position: As required. Max. length 2,000 mm.

- Carriage mounting: T-slots.

- Unit mounting: T-slots or tapped holes in the bearing blocks, mounting sets.

- Belt type: HTD with steel reinforcement, no backlash when changing direction, repeatability ± 0.1 mm

ELZZ

Same functions as ELZ, but each carriage can be moved separately by its own drive. This unit has twin pulleys, which run on separate bearings, and two independent, parallel drive belts, one for each carriage.

- Fitting position: As required. Max. length 4,000 mm without joints.

- Carriage mounting: T-slots.

- Unit mounting: T-slots or tapped holes in the bearing block, mounting sets.

- Belt type: HTD with steel reinforcement, no backlash when changing direction, repeatability ± 0.1 mm

ELZT 40, 60, 60S, 80, 80S, 100

An aluminum square profile with integrated, hardened steel guide rods. Two carriages, which have internal linear ball bearings that can be adjusted free of play, are driven along the guide rods in opposite directions by 2 belts. The pulleys include maintenance-free ball bearings. One belt is tensioned by a device within the carriage. The other timing belt is tensioned by a device within the bearing block. The carriage with the drive block (with motor) is screwed to the crosshead. A T-slot profile is screwed to the carriage as an extension arm which can be adjusted to any length.

- Fitting position: As required. Max. length 3,000 mm.

- Unit mounting: T-slots in the carriage, extension arm

- Belt type: HTD with steel reinforcement, no backlash when changing direction, repeatability +- 0.1 mm

ELFZ 60S, 80S, 100, 125

This special lifting unit consists of an aluminum square profile with hardened steel guide rods. The carriages, which have internal linear ball bearings that can be adjusted free of play, are driven along the guide rods by a timing belt. The rotating timing belt pulleys have maintenance-free ball bearings. One rotation of the drive pulley complies with 1/2 linear circumference of the drive pulley. Belt tension can be readjusted by a simple device in one of the carriages. This device can also be used for symmetrical adjustment of two or more linear units running parallel.

- Fitting position: As required. Max. length without joints 6,000 mm.

- Carriage mounting: T-slots.

- Unit mounting: T-slots or tapped holes in the bearing blocks, or mounting sets.

- Belt type: HTD with steel reinforcement, no backlash when changing direction, repeatability ± 0.1 mm.

ELZG

Mechanical linear unit with two external roller guides. The system is driven by a rotating toothed belt. One carriage is mounted on either side of the belt, so that two carriages move in opposite directions along the complete length of the guide profile.

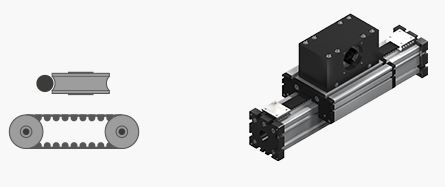

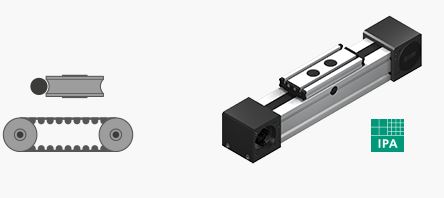

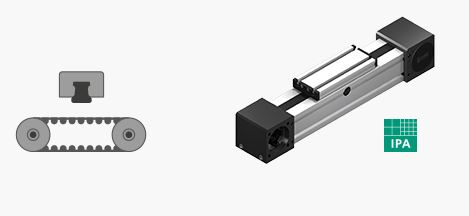

Internal Belt Driven

An aluminum square profile with integrated, hardened steel guide rods. The carriage, which has internal linear ball bearings that can be adjusted free of play, is driven along the guide rods by a timing belt. Toothed pulley has maintenance-free ball bearings. Belt tension can be readjusted by a simple screw adjustment device in the carriage. This device can also be used for symmetrical adjustment of two or more linear units running parallel.

This linear unit is suitable for application in clean rooms of clean-room classification 1,000 (corresponding to US Fed. Standard 209 E).

- Fitting position: As required. Max. length 3,000 mm without joints.

- Carriage mounting: By T-slots.

- Unit mounting: By tapped holes or tapped holes in the bearing block, mounting sets.

- Belt type: HTD with steel reinforcement, no backlash when changing direction, repeatability ± 0.1 mm.

ELHZ 60, 60S, 80, 80S, 100, 125

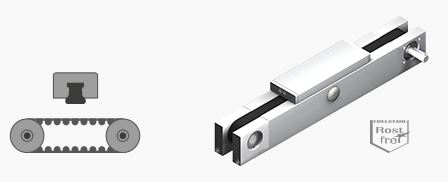

Trapped Belt

MLZ 60, 60S, 80, 80S, 100

An aluminum square profile with integrated, hardened steel guide rods. The carriage, which has internal linear ball bearings, that can be adjusted free of play, is driven along the guide rods by a timing belt. The advantage of this system is that the belt is guided within the profile, ensuring that the belt is always tight and thus enabling the system to be operated e.g. when lying on its side. The pulleys have maintenance-free ball bearings. Belt tension can be readjusted by a simple screw adjustment device in the carriage. This device can also be used

for symmetrical adjustment of two or more linear units running parallel.

- Fitting position: As required, max. length 6,000 mm without joints.

- Carriage mounting: By T-slots.

Unit mounting: By T-slots or tapped holes in the bearing block, mounting sets. - Belt type: HTD with steel reinforcement, no backlash when changing direction, repeatability: ± 0.1 mm.

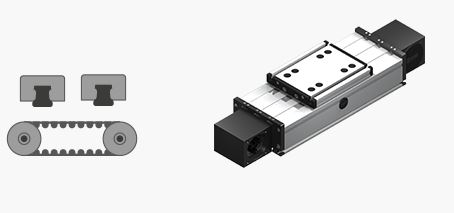

Internal Roller Bearing Guided

QLZ

A square aluminum profile with an integrated roller guide. The carriage is driven by a timing belt. Each standard pulley includes one coupling claw on one side. Belt tension can be readjusted by a simple screw adjustment device in the carriage. This device can also be used for symmetrical adjustment of two or more linear units running parallel.

Suitable for application in clean rooms of clean-room classification 1,000 (corresponding to US Fed. Standard 209 E).

Fitting position: As required. Max. length 6,000 mm without joints.

- Carriage mounting: By T-slots.

- Unit mounting: T-slots and mounting sets. The linear axis can be combined with any T-slot profile.

- Belt performance: HTD with steel reinforcement, no backlash when changing direction, repeatability ± 0.1 mm.

- Carriage support: In the standard version, the carriage runs on 4 rollers which can be a

DLZ

A rectangular aluminum profile with 2 integrated roller guides. The carriage is moved by a belt drive. Each standard pulley has got one coupling claw on one side. Belt tension can be readjusted by a simple screw adjustment device in the carriage. This device can also be used for symmetrical adjustment of two or more linear units running parallel. The openings of the guide body are sealed with 3 stainless steel cover bands to protect the guide from splash water and dust. Alternatively, the opening can also be covered with a bellow or can be delivered without cover bands.

- Fitting position: As required. Max. length 6,000 mm without joints.

- Carriage mounting: T-slots.

- Unit mounting: T-slots and mounting sets. The linear axis can be combined with any T-slot profile.

- Belt type: HTD with steel reinforcement, no backlash when changing direction, repeatability ± 0.1 mm.

- Carriage support: In the standard version, the carriage runs on 8 rollers which can be adjusted and serviced at a central servicing position. For longer carriages the number of rollers can be increased.

DLVZ

A rectangular aluminum profile with 2 integrated roller guides. The carriage is moved by a belt drive. Belt tension can be readjusted by a simple screw adjustment device in the carriage. This device can also be used for symmetrical adjustment of two or more linear units running parallel. The openings of the guide body are sealed with 3 stainless steel cover bands to protect the guide from splash water and dust. Alternatively, the opening can also be covered with a bellow or can be delivered without cover bands.

- Fitting position: As required. Max. length 3,000 mm without joints.

- Carriage mounting: T-slots.

- Unit mounting: T-slots and mounting sets. The linear axis can be combined with any T-slot profile.

- Belt type: HTD with steel reinforcement, no backlash when changing direction, repeatability ± 0.1 mm.

- Carriage support: In the standard version, the carriage runs on 8 rollers which can be adjusted and serviced at a central servicing position. For longer carriages the number of rollers can be increased.

DLSZ

A rectangular aluminum profile with integrated, hardened steel guide rods. The carriage, which has linear ball bearings that can be adjusted free of play, is driven along the guide rods by a timing belt. Each standard pulley includes a coupling claw on one side and is equipped with maintenance-free ball bearings. Belt tension can be readjusted by a simple screw adjustment device in the carriage. This device can also be used for symmetrical adjustment of two or more linear units running parallel.

- Fitting position: As required. Max. length 6,000 mm without joints.

- Carriage mounting: T-slots.

- Unit mounting: T-slots and mounting sets. The linear axis can be combined with any T-slot profile.

- Belt performance: HTD with steel reinforcement, no backlash when changing direction, repeatability ± 0,1 mm.

- Carriage support: In the standard version, the carriage runs on 8 rollers which can be adjusted and serviced at a central servicing

position. For longer carriages the number of rollers can be increased.

Internal Profile Rail Guided

QSZ

A square aluminum profile with an integrated roller guide. The carriage is driven by a timing belt. Each standard pulley includes one coupling claw on one side. Belt tension can be readjusted by a simple screw adjustment device in the carriage. This device can also be used for symmetrical adjustment of two or more linear units running parallel.

Suitable for application in clean rooms of clean-room classification 1,000 (corresponding to US Fed. Standard 209 E).

- Fitting position: As required. Max. length 6,000 mm without joints.

- Carriage mounting: T-slots.

- Unit mounting: T-slots and mounting sets. The linear axis can be combined with any T-slot profile.

- Belt performance: HTD with steel reinforcement, no backlash when changing direction, repeatability ± 0.1 mm.

- Carriage support: In the standard version, the carriage runs on 4 rollers which can be adjusted.

QSZE

A square aluminum profile with an integrated ball rail guide and is covered by a stainless steel sheet (thickness 0.37mm, material 1.4,301). The carriage is moved by a belt drive. Belt tension can be readjusted by a simple screw adjustment device in the carriage. This device can also be used for symmetrical adjustment of two or more linear units running parallel.

- Fitting position: As required. Max. length 3,000 mm without joints.

- Carriage mounting: T-nuts and bores through the cover.

- Unit mounting: T-nuts and bores through the cover.

- Belt performance: HTD with kevlar reinforcement, no backlash when changing direction, repeatability ± 0.1 mm.

- Carriage support: In the standard version, the carriage runs on two runner blocks which can be adjusted and serviced at a central servicing position. For longer carriages the number of runner blocks can be increased.

DSZ

A rectangular aluminum profile with 2 integrated rail guides. The carriage is moved by a belt drive. Each standard pulley has got one coupling claw on one side. Belt tension can be readjusted by a simple screw adjustment device in the carriage. This device can also be used for symmetrical adjustment of two or more linear units running parallel. The openings of the guide body are sealed with 3 stainless steel cover bands to protect the guide from splash water and dust. Alternatively, the opening can also be covered with a bellow or can be delivered without cover bands.

- Fitting position: As required. Max. length 6,000 mm without joints.

- Carriage mounting: T-slots.

- Unit mounting: T-slots and mounting sets. The linear axis can be combined with any T-slot profile.

- Belt type: HTD with steel reinforcement, no backlash when changing direction, repeatability ± 0.1 mm.

- Carriage support: In the standard version, the carriage runs on 4 runner blocks which can be serviced at a central servicing position.

For longer carriages the number of runner blocks can be increased.

DSSZ

A rectangular aluminum profile with integrated rail guides. The carriage, which has runner blocks, is driven by a timing belt. Each standard pulley includes a coupling claw on one side and is equipped with maintenance-free ball bearings. Belt tension can be readjusted by a simple screw adjustment device in the carriage. This device can also be used for symmetrical adjustment of two or more linear units running parallel.

- Fitting position: As required. Max. length 6,000 mm without joints.

- Carriage mounting: T-slots.

- Unit mounting: T-slots and mounting sets. The linear axis can be combined with any T-slot profile.

- Belt performance: HTD with steel reinforcement, no backlash when changing direction, repeatability ± 0,1 mm.

- Carriage support: In the standard version, the carriage runs on 4 runner blocks. For longer carriages the number of runner blocks can be increased.

QSSZ

A square aluminum profile with integrated rail guidance. The carriage, which has runner blocks, is driven by a timing belt. Each standard pulley includes a coupling claw on one side and is equipped with maintenance-free ball bearings. Belt tension can be readjusted by a simple screw adjustment device in the carriage. This device can also be used for symmetrical adjustment of two or more linear units running parallel.

- Fitting position: As required. Max. length 3,000 mm without joints.

- Carriage mounting: T-slots.

- Unit mounting: T-slots and mounting sets. The linear axis can be combined with any T-slot profile.

- Belt performance: HTD with steel reinforcement, no backlash when changing direction, repeatability ± 0.1 mm.

- Carriage support: In the standard version, the carriage runs on 2 runner blocks which can be serviced at a central servicing position. For longer carriages the number of runner blocks can be increased.

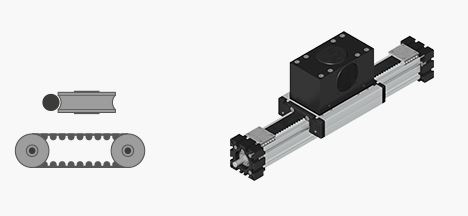

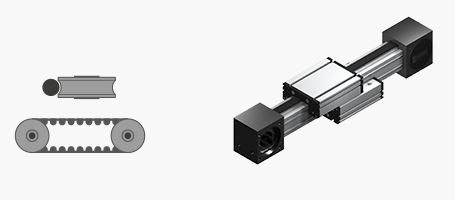

V Groove Guided

EGZ 30, 40, 60, 60S, 80

An aluminum square profile with lateral V-guides. The carriage that can be adjusted free of play is driven along the V-guides by a timing belt. The pulleys have maintenance-free ball bearings. Belt tension can be readjusted by a simple screw adjustment device in the carriage. This device can also be used for symmetrical adjustment of two or more linear units running parallel.

- Fitting length: As required. Max. length 6,000 mm without joints.

- Carriage mounting: T-slots

- Unit mounting: T-slots or tapped holes in the bearing block, mounting sets.

- Belt type: HTD with steel reinforcement, no backlash when changing direction, repeatability: ± 0.1 mm.

Need Help Selecting Modular Linear Actuators?

Collaborate with one of our technical experts on the specifics of your application to ensure the ideal product fit that best meets your performance requirements and budget.